PRODUCT PARAMETERS

Description

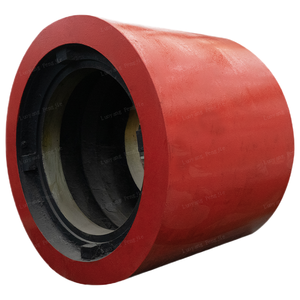

Introduction to towed Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer)

Specification of Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer

The whole spare component for Liebherr undercarriage excavators and bulldozer components satisfies stringent top quality criteria. These components ensure reliable performance in sturdy operations. The components consist of track chains, rollers, idlers, gears, and track shoes. Top-quality steel creates the base material. This improves longevity under extreme stress. Each component undertakes warm treatment. This procedure raises resistance to deterioration. Accuracy machining assurances exact fitment. Compatibility covers Liebherr versions like R 900, R 976, and PR 776.

The track chains feature solidified pins and bushings. These lower rubbing during activity. Sealed lube networks maintain smooth operation. Rollers and idlers make use of enhanced bearings. These handle hefty tons without deformation. Gears have laser-cut teeth. This ensures optimum involvement with track chains. Track footwear include bolt holes for very easy substitute. Their layout stops mud accumulation. This enhances traction on uneven terrain.

Surface coatings shield versus corrosion and corrosion. Electroplating adds an extra layer of protection. Components stand up to abrasion from rocks and particles. Testing includes tension simulations. Each part must pass lots ability checks. Quality assurance confirms no issues before shipping.

These components extend the life expectancy of undercarriage systems. Regular use minimizes downtime for repair services. Maintenance comes to be simpler with standardized layouts. Professionals can install them without specialized tools. Supply availability ensures quick replacements. International providers support fast distribution.

Efficiency stays consistent in extreme atmospheres. Parts operate in temperature levels from -30 ° C to 50 ° C. Waterproof seals stop damage in wet problems. Dust-resistant features maintain internal parts tidy. Compatibility with OEM requirements prevents functional mismatches.

Expense performance originates from long service periods. Lowered wear lowers complete possession costs. Mass getting choices offer additional cost savings. Customized orders fit one-of-a-kind task demands. Technical support aids with setup inquiries. In-depth handbooks lead correct assembly steps.

Safety requirements line up with sector regulations. Sure styles stop unexpected break downs. Rigorous testing ensures conformity with Liebherr’s guidelines. Each part carries an identification number for traceability. Guarantee coverage shields against manufacturing imperfections.

(Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer)

Applications of Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer

Whole extra components for Liebherr undercarriage excavators and bulldozers play an essential function in keeping hefty machinery running smoothly. These elements make certain equipments manage tough jobs like digging, training, and relocating products in building, mining, and earthmoving jobs. Premium undercarriage parts support the device’s weight, minimize wear, and keep security throughout operation.

Track chains and rollers are key components of the undercarriage system. They aid disperse the device’s weight evenly throughout irregular terrain. This prevents too much tension on individual parts. Worn-out track chains or rollers bring about uneven activity, greater gas usage, and much faster part failure. Changing them with genuine Liebherr sprockets and idlers makes certain smooth rotation and alignment. This minimizes downtime and prolongs the machine’s functioning life.

Track shoes and bolts are another necessary category. Track shoes supply grip on loosened or unsafe surface areas. They shield the undercarriage from direct contact with rocks, debris, or abrasive materials. Harmed track footwear lower grip and boost the danger of crashes. High-strength screws maintain the track web links securely fastened. Normal inspection and substitute of these parts prevent unexpected break downs throughout crucial jobs.

Carrier rollers and overview wheels keep correct track tension. Loose tracks cause derailments or excessive resonance. Limited tracks strain the engine and components. Real Liebherr components make certain exact adjustments. This maintains the maker stable and effective popular atmospheres like quarries or demolition websites.

Using authentic Liebherr undercarriage parts warranties compatibility and efficiency. Aftermarket or low-quality substitutes may conserve expenses originally however typically fall short too soon. This causes much more regular repair work and greater lasting expenses. Trustworthy extra parts reduce upkeep needs and keep jobs on schedule.

Heavy-duty applications call for components built to sustain extreme pressure, wetness, and temperature changes. Liebherr elements make use of advanced products and design. They resist deterioration, take care of heavy tons, and preserve structural stability with time. Operators benefit from regular maker efficiency, reduced repair expenses, and enhanced safety.

Normal upkeep with real parts makes certain excavators and excavators run at peak performance. Proper care of the undercarriage system directly impacts efficiency and task timelines. Buying high quality extra parts secures devices worth and sustains long-lasting functional success.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer

Whole spare parts for Liebherr undercarriage excavators and bulldozers ensure machines work properly. Below are common questions users ask.

What parts make up the undercarriage? The undercarriage includes tracks, rollers, sprockets, idlers, and chains. These parts support the machine’s weight and help it move. Regular inspection keeps them functioning.

Why use genuine Liebherr parts? Genuine parts match original specs. They last longer and handle heavy loads better. Non-genuine parts might save money short-term but cause breakdowns faster. Using authentic parts avoids warranty issues.

How often should undercarriage parts be replaced? Replacement depends on usage. Machines in rocky or muddy terrain wear parts faster. Check for cracks, uneven wear, or loose components monthly. Replace damaged parts immediately to prevent bigger problems.

How do I pick the right spare parts? Match the part number to your machine’s model. Check the excavator or bulldozer’s manual for exact codes. Contact a dealer if unsure. Wrong parts strain the undercarriage and reduce efficiency.

Where can I buy reliable undercarriage parts? Buy from authorized Liebherr dealers or certified suppliers. They guarantee quality and compatibility. Avoid unverified sellers online. Authentic suppliers provide support for installation and troubleshooting.

(Whole Spare Part For Liebherr Undercarriage Excavators Parts Bulldozer)

REQUEST A QUOTE

RELATED PRODUCTS

R250LC-7 Excavator Dial Fuel Switch 21N8-20502 Throttle Knob

Crawler Excavator Final Drive Travel Gearbox Planetary Gear Carrier Assy Swing Reduction Gearbox Reducer

HAOHONG Mini Digger Excavator Machine Attachment Accessory Quick hitch Narrow Bucket Grapple

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks

Excavator Parts Injector Diesel 21340612 BEBE4D24002 Nozzle Injector VOE21340612 D13 Engine Injector