PRODUCT PARAMETERS

Description

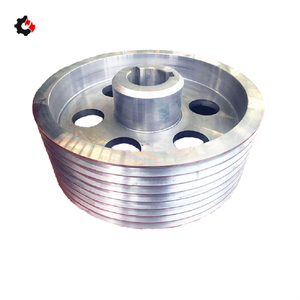

Introduction to towed Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts)

Specification of Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts

The undercarriage excavator components for dozers and mini excavators are developed to take care of tough problems. These parts fit Sany, Liebherr, and D3C Excavator designs. The track chains make use of high-carbon steel. This makes them solid versus wear and heavy tons. Each link is heat-treated for added hardness. Rollers and carrier rollers support the track movement. They have sealed bearings inside. This maintains dust out and oil in. The style lowers rubbing, so components last longer.

Sprockets suit the track chain pitch precisely. This prevents sliding and unequal wear. Gears are built, not cast. Creating makes them harder under stress. Idlers maintain the tracks straightened. They readjust tension instantly. This quits the tracks from obtaining too loosened or tight. Track shoes are available in various patterns. Select criterion, swamp, or rock holds based on the ground. All footwear bolt on easily. They spread the equipment’s weight equally to prevent sinking.

Bushings and pins link the track links. They are hardened to resist grinding. Regular greasing quits them from confiscating. These parts work in mud, rocks, or sand. They handle high effects without splitting. All materials fulfill ISO criteria. Examinations look for solidity, tons capacity, and corrosion resistance.

The undercarriage parts are produced very easy exchanging. No unique devices are required. Precise sizing guarantees they fit Sany SY60, Liebherr R914, and D3C Excavator models. Compatibility is verified before delivery. Stock consists of new and reconstructed alternatives. Rebuilt components save cash but work like new.

These elements concentrate on sturdiness. They cut downtime and repair work costs. Seals and layers protect against rust. Every part is evaluated for imperfections. OEM specifications guide manufacturing. This guarantees top quality suits original devices. Orders deliver with setup guides. Technical support assists with troubleshooting.

The undercarriage systems handle mining, building, and farming work. Durable builds make it through lengthy hours of usage. Precision engineering maintains makers stable. Appropriate upkeep prolongs component life. Change worn sections early to stay clear of bigger solutions. Stock covers worldwide shipping. Preparations are short for urgent needs.

(Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts)

Applications of Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts

Undercarriage components for excavators and excavators are crucial for keeping heavy machinery running efficiently. These parts manage heavy lots, harsh surface, and continuous stress and anxiety. Premium undercarriage parts ensure devices like Sany mini excavators, Liebherr D3c excavators, and Dozer mini excavators function effectively. Durable tracks, rollers, and gears are crucial to preventing malfunctions. Without trustworthy components, equipment can deal with enhanced downtime and fixing expenses.

These components are developed to endure extreme problems. Mining, building, and landscape design tasks demand challenging undercarriage systems. Sany mini excavator parts, for instance, are made for stability on uneven ground. Liebherr D3c bulldozer parts concentrate on accuracy and load-bearing ability. Tiny excavator components prioritize compact stamina for limited areas. Using components made from hardened steel or alloy increases life-span. Effectively maintained undercarriages lower endure various other machine parts.

Compatibility matters when changing parts. Each equipment version has unique specs. Sany, Liebherr, and Dozer undercarriage parts are crafted to fit exact dimensions. This makes sure smooth operation and avoids alignment issues. Tailor-made parts additionally enhance gas efficiency by lowering friction. Operators notification smoother activity and much better control throughout tasks.

Regular inspections assist area early signs of damage. Broken tracks or used rollers should be changed promptly. Postponing repairs dangers more considerable damage. Real replacement parts assure performance suits original equipment. Third-party or low-grade components may save money ahead of time however frequently stop working quicker. Investing in reputable undercarriage elements decreases lasting expenses.

Vendors using these components typically provide thorough requirements. Buyers ought to verify compatibility with their equipment design. Expert assistance teams can aid in picking the appropriate parts. Mass purchasing options are readily available for big projects or fleet upkeep. Fast shipping makes certain very little downtime throughout replacements.

Maintaining undercarriage systems expands the life of excavators and excavators. Appropriate treatment guarantees devices provide regular power and accuracy. Selecting the ideal components directly impacts performance and safety on job websites.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts

Undercarriage parts for excavators and dozers need regular maintenance. Common questions come up about compatibility, durability, and sourcing. Here are answers to five frequent queries.

What undercarriage parts fit a Sany mini excavator? Sany mini excavators use specific track chains, rollers, and idlers. Check the model number and machine specifications before ordering. Parts for Sany SY16C or SY35U differ from larger models. Cross-reference part numbers with supplier lists to avoid mismatches.

Are Liebherr excavator undercarriage components interchangeable with other brands? Liebherr parts follow unique design standards. Using non-OEM parts risks poor fit or premature wear. Always confirm compatibility with Liebherr’s technical guides. Third-party options exist but verify quality certifications match OEM requirements.

How long do D3C bulldozer undercarriage parts last? Lifespan depends on operating conditions. Rocks, mud, or abrasive terrain accelerate wear. High-quality sprockets and track shoes last 1,500–2,000 hours with proper care. Inspect components monthly for cracks or uneven wear. Replace damaged parts immediately to avoid further damage.

What maintenance prevents undercarriage failures? Clean mud and debris after each use. Lubricate pins and bushings regularly to reduce friction. Tighten loose track bolts to maintain alignment. Check track tension weekly—over-tightening strains parts, while loose tracks derail easily. Follow the manufacturer’s service schedule for optimal performance.

Where can I find affordable undercarriage parts without compromising quality? Reliable suppliers offer aftermarket parts tested for durability. Compare material grades—opt for heat-treated steel rollers or hardened track links. Bulk purchasing lowers costs for items like seals or bolts. Read customer reviews to confirm part reliability before buying.

Choosing the right undercarriage parts ensures machine efficiency. Prioritize exact measurements, material quality, and supplier reputation. Regular inspections and timely replacements reduce downtime and repair costs.

(Undercarriage Excavator For Spare Part Dozer Mini excavator parts for sany for liebherr D3c Bulldozer Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Construction Machinery Parts Tilting Grading Bucket Swing Bucket Excavator Tilt Mud Bucket

Dragline Excavator 34XH1M Mechanical high quality Long eccentric shaft Metal Balance Forging Steel large Crank Shaft

High Durable Excavator Thumb Bucket Grapple Excavator Grab Bucket

Crawler Excavator Final Drive Travel Gearbox Planetary Gear Carrier Assy Swing Reduction Gearbox Reducer

Factory Excavator Track Roller Top Bottom Roller U30 U35 RX303 RX403 Undercarriage Parts