PRODUCT PARAMETERS

Description

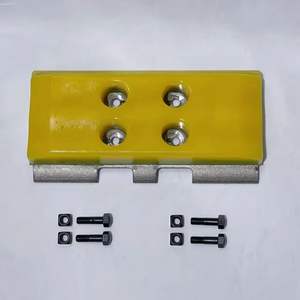

Introduction to towed OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU)

Specification of OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU

OEM construction equipment extra components make certain dependable efficiency and extensive devices life. Provider rollers, excavator undercarriage components, and leading rollers for pet cat and KOMATSU makers meet strict high quality standards. These components manage heavy tons and rough problems. They are made from high-grade steel. This product withstands wear and impact. Precision machining assurances exact measurements. Appropriate fit reduces stress and anxiety on nearby components.

Carrier rollers sustain track chains. They maintain positioning throughout procedure. Smooth rotation reduces rubbing. This stops premature track wear. Top rollers assist tracks and disperse weight uniformly. Both parts go through warmth treatment. Surface area hardening boosts toughness. Inner durability stays undamaged. This equilibrium prevents splits under stress.

Excavator undercarriage components include rollers, idlers, and track links. These form the device’s structure. Robust construction makes certain security on irregular surface. Elements are checked for fatigue resistance. Simulated work confirm long life. Sealed lubrication systems keep pollutants out. Inner bearings stay secured. Upkeep periods prolong. Downtime decreases.

Compatibility matters. Components match CAT and KOMATSU models specifically. Screw patterns, bore dimensions, and thread kinds straighten with original specs. Interchangeability simplifies substitutes. No modifications are needed. Operators swap parts swiftly. Equipment schedule enhances.

Surface area therapies stop corrosion. Electroplating or finish includes corrosion resistance. Parts endure wet or abrasive environments. Seals and gaskets obstruct dirt and dampness. Inner parts remain clean. Lubrication lasts much longer. Friction-related failings drop.

Rigorous top quality checks happen at every phase. Raw materials are evaluated initially. Dimensional accuracy is confirmed post-machining. Tons tests confirm performance limitations. Malfunctioning systems obtain denied early. Final products satisfy OEM demands.

Inventory covers usual and unusual versions. Stock accessibility lowers wait times. Customized orders accommodate one-of-a-kind demands. Technical assistance assists with setup questions. Teams advise optimal part combinations.

These parts suit excavators, excavators, and loaders. Mining, building, and forestry applications benefit. Reliable undercarriage systems enhance project effectiveness. Equipment stays functional much longer. Fix expenses stay low.

(OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU)

Applications of OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU

OEM construction equipment extra components like carrier rollers, excavator undercarriage components, and top rollers play a key function in keeping heavy equipment running smoothly. These parts are designed for equipments from brand names like feline and KOMATSU. They make sure stability, sustain the weight of the devices, and manage hard conditions during excavating, lifting, or relocating materials.

Provider rollers and top rollers are critical for the undercarriage system. They lead the track chain and disperse the machine’s tons equally. This reduces anxiety on various other elements. Excavator undercarriage components shield the device’s framework and tracks from wear brought on by rough terrain, rocks, or particles. Without these components, makers would deal with faster break downs and greater repair service prices.

These OEM parts are utilized in mining, building, and farming. They operate in atmospheres where dirt, mud, and hefty lots are common. OEM carrier rollers and top rollers are built to match the original specs of CAT and KOMATSU makers. This makes certain a perfect fit. It prevents placement problems or premature wear that generic parts may trigger.

Durability is a major benefit. OEM parts use high-grade materials like forged steel and advanced alloys. They undertake strict testing to handle extreme stress and weather condition. This expands the life-span of the undercarriage system. It also lowers the danger of unintended downtime.

Utilizing OEM undercarriage parts conserves cash with time. Dependable components mean fewer substitutes and repairs. They maintain maker efficiency, lower fuel usage, and prevent damages to nearby components. Professionals count on OEM parts since they satisfy the same standards as the original equipment. They are very easy to source, with lots of providers supplying fast delivery. This keeps jobs on time.

OEM carrier rollers, top rollers, and undercarriage parts are vital for heavy equipment. They offer the toughness and accuracy needed for requiring jobs. Selecting OEM over aftermarket choices warranties compatibility and dependability. It supports the device’s capacity to function effectively in tough conditions.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU

OEM construction machinery spare parts ensure equipment runs smoothly. Here are common questions about carrier rollers, excavator undercarriage parts, and top rollers for CAT and Komatsu machines.

What makes OEM parts better than aftermarket ones?

OEM parts match original specs exactly. They are made by the same manufacturers supplying CAT and Komatsu. Aftermarket parts might save money but often lack quality control. OEM parts last longer and prevent breakdowns.

How do I confirm these parts fit my machine?

Check the model number of your equipment first. Cross-reference it with the part numbers listed in product descriptions. Contact the supplier directly if unsure. They usually have databases or experts to verify compatibility.

Why do carrier rollers and top rollers wear out quickly?

These parts handle heavy loads and constant friction. Poor maintenance speeds up wear. Harsh conditions like mud, rocks, or extreme temperatures also reduce lifespan. Using OEM parts ensures materials and design withstand these stresses better.

Can I replace these parts myself?

Basic mechanical skills and tools are needed. Follow the service manual for your machine. Incorrect installation risks damaging the undercarriage. Hire a certified technician if you lack experience. Safety matters more than saving time or money.

How do I spot fake OEM parts?

Buy from authorized dealers only. Fake parts often have blurry logos, flimsy packaging, or spelling errors. Genuine parts include certificates of authenticity. Compare prices—if a deal seems too good, it likely is.

Regular maintenance extends part life. Clean the undercarriage often. Check for abnormal wear or loose components. Lubricate moving parts as the manual recommends. Replace damaged rollers immediately to avoid further damage.

(OEM Construction Machinery Spare Parts Carrier Roller Excavator Undercarriage Parts Top Roller For CAT KOMATSU)

REQUEST A QUOTE

RELATED PRODUCTS

53103205 Construction Machinery Excavator Spare Part Casting Steel Bucket Teeth For Jcb