PRODUCT PARAMETERS

Description

Introduction to towed Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction)

Specification of Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction

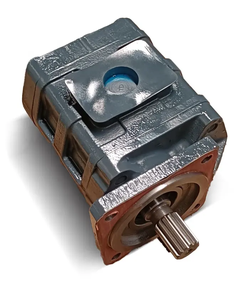

Warm excavator extra parts supply top performance for building machinery. These components match PC200 models. They are constructed to last. Top notch materials make them solid. You obtain trustworthy replacements for initial parts. These aftermarket components satisfy rigorous criteria. They work in difficult conditions. Sturdy steel and advanced alloys resist wear. Each part goes through testing. This guarantees it deals with heavy loads. Accuracy design matches factory specifications. The parts fit flawlessly. This prevents breakdowns. Hydraulic pumps, track rollers, and container pins are available. These parts bring back device function. They maintain projects on time.

Performance matters. These parts increase efficiency. Smooth operation reduces fuel use. Heat-treated parts avoid fractures. Seals and bearings are tested for leaks. This extends component life. Compatibility is crucial. Every component fits PC200 excavators. Precise measurements avoid installation concerns. No adjustments are required. This saves time.

Quality assurance is rigorous. Each set is examined prior to delivery. Examinations consist of stress checks and stress simulations. Accreditations satisfy international criteria. Vendors resource products from trusted mills. This guarantees uniformity.

Aftermarket parts cost much less than OEM alternatives. You save cash without giving up high quality. Supply covers usual substitutes. Orders ship quickly. Downtime is reduced. Technical assistance assists with setup. Groups address questions swiftly.

These parts work in mining, roadwork, and demolition. They take care of dust, mud, and extreme temperature levels. Normal usage shows no very early wear. Upkeep periods stay the very same. Equipments stay effective longer.

Pick these components for dependability. They match the original layout. Efficiency meets expectations. Develop top quality ensures years of service. Supply is updated routinely. New kid on the block cover even more parts. Personalized requests are approved. Mass orders get discount rates. Shipping choices match immediate demands.

Trust these premium construction machinery components. They maintain your PC200 excavator running. No compromises. No delays.

(Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction)

Applications of Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction

Warm excavator spare components play a vital role in maintaining building machinery running efficiently. Top notch aftermarket components for models like the PC200 guarantee devices take care of laborious without damaging down. These parts work well in mining, roadway building, demolition, and other durable tasks. Their toughness issues because building websites need tools that lasts.

Mining operations count on hot excavator parts to dig, tons, and move materials. The PC200’s aftermarket parts withstand severe warmth and pressure. This decreases downtime and maintains tasks on time. Roadway building makes use of these parts for jobs like grading and trenching. Solid parts imply less fixings, saving time and money.

Demolition sites require hard equipment to damage concrete and clear particles. Top quality extra components deal with hefty influences without failing. Earthmoving tasks also benefit. Aftermarket parts for the PC200 make sure specific control when moving big amounts of soil or rock. This precision improves efficiency and safety.

Agriculture and forestry markets use these components too. Clearing land or taking care of heavy logs requires trustworthy equipment. Heat-resistant materials in warm excavator components protect against wear in high-friction settings. This expands the maker’s life expectancy even with daily use.

Quality matters when selecting aftermarket parts. Economical options could save money ahead of time yet trigger regular failures. Genuine-grade products and accurate design make PC200 components a smart financial investment. They match initial specifications, ensuring compatibility and performance.

Routine upkeep with top-tier components stays clear of unanticipated repair work. Building and construction projects face tight target dates. Equipment failings bring about delays and greater prices. Utilizing relied on aftermarket components keeps devices functioning longer.

Cost-effectiveness is another advantage. Top notch parts last longer, minimizing substitute frequency. This reduces long-lasting expenses while keeping efficiency. Companies conserve cash without giving up efficiency.

Warm excavator extra components sustain many industries. Their stamina and integrity make them crucial for hefty machinery. Choosing the most effective aftermarket options makes sure projects complete promptly and within budget.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction

1. What makes your PC200 aftermarket parts high quality? The parts use top-grade materials. They follow strict production processes. Each part undergoes thorough testing. This ensures they meet original equipment standards. The parts handle heavy workloads. They resist wear and tear. Performance stays stable over time. Customers report fewer breakdowns.

2. Are these parts compatible with PC200 excavators? Yes. The parts are designed for PC200 models. Exact measurements match original specs. Installation requires no modifications. Check your machine’s model number. Confirm the part number matches your needs. Compatibility issues are rare. Contact support for double-checking.

3. How long do these parts last compared to OEM parts? Their lifespan matches OEM parts. They use similar metals and coatings. Stress tests prove equal durability. Proper maintenance extends their life. Harsh conditions might reduce longevity. Most users see no difference.

4. Why choose aftermarket parts over genuine ones? Aftermarket parts cost less. Quality remains high. Production skips brand-name markup. Suppliers focus on function over branding. Savings reach 30-50%. Performance stays reliable. Budget-conscious projects benefit most.

5. What if a part fails or doesn’t fit? Returns and replacements are straightforward. Contact customer service within 14 days. Provide order details and photos. A new part ships fast. Refunds happen if the fault is confirmed. Support teams solve issues quickly.

(Hot excavator spare parts high quality high quality construction machinery parts best PC200 aftermarket construction)

REQUEST A QUOTE

RELATED PRODUCTS

Construction Machinery Parts QSK23-C 6D170-3 Diesel Engine Excavator Assembly for Cummins

Construction Machinery Parts Bulldozer Excavator Undercarriage Parts Track Roller Track Chain Link Idler Carrier Roller For

P550388 HF6710 Diesel engine part hydraulic oil filter excavator engine accessories Replacement for DONALDSON