PRODUCT PARAMETERS

Description

Introduction to towed Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage)

Specification of Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage

Finding the right undercarriage parts keeps your PC200 BD2G mini excavator moving. We supply heavy-duty rubber tracks and components built tough. Our parts match original specifications for a perfect fit and reliable performance.

Our replacement rubber tracks fit the PC200 BD2G exactly. They are the standard width for this machine model. The tracks feature strong internal steel cords. These cords prevent stretching and tearing under heavy loads. The rubber compound itself is high-abrasion resistant. It handles rocks, mud, and rough terrain without quick wear. Tread patterns provide excellent grip. This minimizes slippage on slopes or loose ground. Track hardness is optimized for balance. It offers traction but also protects the ground surface.

Sprockets engage the track links smoothly. We offer sprockets matching the original tooth profile and pitch. They are precision-machined from high-carbon steel. This steel withstands constant impact and wear. Proper sprocket engagement reduces stress on the entire track chain. It prevents premature track failure.

Idler wheels maintain proper track tension. Our idlers match the original diameter and width. Sealed bearings inside keep out dirt and water. This ensures smooth rotation and long service life. Heavy-duty rollers support the track chain along its length. Upper and lower rollers are available. They feature robust seals and hardened surfaces. This combats wear from constant friction and debris.

Track chains link everything together. Our chains use forged alloy steel links. Bushings and pins are induction hardened. This creates an extremely durable wearing surface. Proper lubrication extends chain life significantly. All pins and bushings meet OEM size standards. This guarantees correct fit with sprockets and rollers.

Using genuine-specification undercarriage parts is critical. It ensures optimal machine performance and stability. Correct parts reduce vibration and operator fatigue. They also lower your total operating costs. Less downtime means more productivity. Fewer repairs save money over the machine’s lifespan.

(Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage)

Applications of Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage

Mini crawler excavators like the Komatsu PC200 depend heavily on their undercarriage parts. These parts take constant punishment. The rubber tracks, sprockets, rollers, and idlers form the foundation keeping the machine moving. Replacing worn parts is not optional. It’s essential maintenance. Rubber tracks face rocks, mud, and debris daily. They crack, tear, or wear thin over time. Running damaged tracks risks sudden failure. This stops work immediately. Good quality replacement rubber tracks restore grip and stability. They prevent slippage on slopes or loose ground. This keeps the excavator productive and safer for the operator.

Sprockets drive the tracks. Their teeth mesh with the track links. Worn sprocket teeth don’t engage properly. This causes uneven track wear and jumping. Premature track failure often follows. Replacing sprockets at the right time protects your new tracks. Bottom rollers support the machine’s weight across the track length. Top rollers guide the track’s return path. Seized or damaged rollers create friction. This increases strain on the tracks and the engine. It wastes fuel. Smooth rolling idlers and rollers are vital. They reduce track resistance and operating costs.

Ignoring undercarriage wear is expensive. Parts wear out faster together. Replacing one worn part puts extra stress on others. A damaged idler can ruin a new track quickly. Replacing key components together makes sense. It extends the life of the whole system. Regular inspection spots problems early. Look for abnormal track wear patterns, visible cracks, or uneven roller surfaces. Catching wear early saves money. It avoids bigger repairs later. Quality undercarriage parts matter. They fit correctly. They last longer under tough conditions. Using genuine or high-grade aftermarket parts ensures reliability. Your PC200 BD2G needs tough parts to keep digging. Investing in the right track, sprocket, roller, and idler replacements means less downtime. Your machine works harder for longer.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage

What are the main parts of the PC200 BD2G rubber track undercarriage? The undercarriage has rubber tracks, drive sprockets, idlers, rollers, and track chains. These pieces connect to form a complete system. The rubber tracks touch the ground directly. Sprockets drive the tracks. Idlers and rollers guide the tracks. Chains link everything securely. This setup handles weight and movement.

How often should I inspect the undercarriage parts? Check every 250 hours of operation. Look for visible wear or damage. Measure track tension during these checks. Early detection prevents bigger failures. It avoids costly downtime. Regular maintenance extends part life. Ignoring checks risks machine breakdowns.

What signs mean the rubber tracks need replacing? Watch for deep cracks or chunks missing from the track surface. Notice if tracks slip frequently or tension changes often. Excessive vibration during operation is another clue. Worn tracks reduce grip. They make steering harder. Delaying replacement damages other undercarriage parts.

Can I replace just one damaged part or the whole undercarriage set? Replace a single part if only one component fails. But if multiple parts show wear, change the entire set. Mixing old and new parts strains the system. It causes uneven wear. Replacing everything together ensures balanced performance. It saves money long-term.

How do I pick the correct spare parts for my PC200 BD2G? Match parts exactly to your excavator model. Use the machine’s serial number when ordering. Wrong parts cause poor fit or malfunctions. They accelerate wear on other components. Genuine parts guarantee compatibility. Always verify specifications before buying.

(Heavy earthmoving machinery Spare Parts for mini crawler excavator PC200 BD2G track rubber track undercarriage)

REQUEST A QUOTE

RELATED PRODUCTS

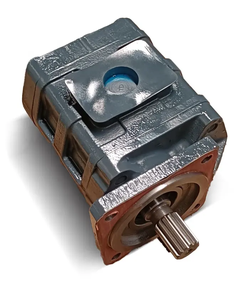

Hydraulic Gear Pump Pilot Pump KX165 Kubota 165 For Excavator Spare Parts

DIGEER Fast delivery excavator undercarriage spare parts rubber track KH-026 for construction work

Excavator Spare Parts Front Idler Wheel Undercarriage Spare Parts Front Steel Carrying Idler Roller PC340

Excavator Undercarriage Spare Parts Excavator Track Link Chain Guard

Dragline Excavator Parts long large diameter gear shaft drive Big gear shaft