PRODUCT PARAMETERS

Description

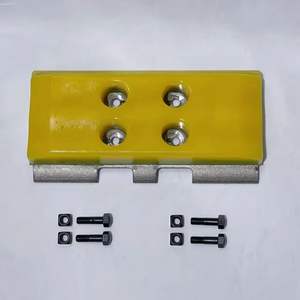

Introduction to towed Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller)

Specification of Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller

Manufacturing facility building equipment parts include excavator undercarriage parts, bulldozer spare parts, gears, idlers, and track rollers. These components ensure smooth procedure and sturdiness in sturdy building atmospheres. Excavator undercarriage parts support the machine’s weight and activity. They consist of track chains, rollers, and frames. Built to handle rough terrains, these components lower wear and extend devices life. Premium steel or alloy materials make them resistant to impact and abrasion. Routine maintenance of undercarriage components protects against malfunctions and expensive repair work.

Bulldozer spare components cover components like blades, rippers, and hydraulic systems. These components make it possible for effective earth-moving and grading tasks. Sturdy materials ensure they endure high anxiety and constant use. Appropriately working bulldozer components improve task site efficiency and lower downtime. Compatibility with major excavator brands ensures simple substitute and installment.

Sprockets drive the track chain in excavators and excavators. They mesh with track links to move the machine ahead or backward. Precision-engineered sprockets guarantee smooth power transmission. Hard teeth resist wear from friction. Matching gear dimension to the track chain prevents premature failure. Idlers lead the track chain and preserve tension. Placed at the front of the undercarriage, they absorb shocks and lower track sagging. Robust idlers decrease track derailment threats. Sealed bearings inside idlers protect versus dust and moisture.

Track rollers sustain the maker’s weight and maintain the track chain aligned. They rotate as the equipment relocations, lowering rubbing between the track and frame. Durable rollers deal with severe lots without deformation. Heat-treated surfaces improve longevity. Routine lubrication of rollers guarantees smooth operation. These components come in standard or custom sizes to fit various equipment designs.

All manufacturing facility building equipment components go through rigorous top quality checks. Examining consists of cardiovascular test, material evaluation, and performance tests. This guarantees reliability under real-world problems. Components are readily available individually or as packages for full undercarriage overhauls. Providers provide technological support for part choice and installment. Stock accessibility makes sure quick distribution to decrease task hold-ups. Picking authentic components assurances compatibility and maximizes tools life expectancy.

(Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller)

Applications of Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller

Manufacturing facility construction machinery components play essential roles in maintaining hefty tools running. Excavator undercarriage components develop the base of the equipment. These components deal with heavy lots and harsh terrain. Sprockets, idlers, and track rollers are essential parts. Gears attach the excavator’s track chain to the engine. They transfer power to move the equipment. Worn sprockets trigger track slippage and decrease performance. Routine assessment ensures they stay lined up and useful. Idlers assist the track chain and maintain tension stable. Appropriately changed idlers stop tracks from loosening up or hindering. Track rollers support the device’s weight and assist the tracks move efficiently. Damaged rollers boost friction and stress on various other parts. Replacing them early avoids costly breakdowns.

Bulldozer spare components include blades, rippers, and hydraulic parts. Blades press dirt, rocks, and particles. Durable blades take care of high-impact jobs without bending. Rippers break difficult ground or rock surfaces. Strong ripper teeth are vital for efficient earthwork. Hydraulic systems manage blade motion and pressure. Leakages or used hoses disrupt operations. Regular checks preserve hydraulic performance.

Track systems for excavators and bulldozers encounter consistent wear. Severe atmospheres like mines or building sites speed up damages. High-grade undercarriage parts last longer under stress. Steel alloys and heat-treated surfaces enhance durability. Selecting the appropriate parts reduces downtime and repair expenses.

Extra parts need to match initial specs. Wrong sizes or materials cause breakdowns. Credible providers offer licensed parts. Authentic parts make certain compatibility and integrity. Stocking essential spares decreases project delays.

Normal upkeep extends equipment life. Cleansing undercarriages eliminates particles that increases wear. Lubing gears and rollers reduces friction. Checking track tension prevents uneven wear patterns. Operators must report unusual sounds or vibrations quickly. Quick fixes stop small concerns from becoming major troubles.

Manufacturing facility construction equipment parts maintain projects on schedule. Trustworthy excavator undercarriage parts and excavator saves ensure regular performance. Buying quality parts conserves money and time. Devices remains functional popular problems.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller

Factory construction machinery parts like excavator undercarriage components are crucial for heavy equipment performance. Here are answers to common questions about these parts. What do excavator undercarriage parts do? These parts support the machine’s weight, provide stability, and enable movement on rough terrain. The sprocket drives the track chain, the idler maintains track tension, and the track roller guides the tracks. Regular maintenance ensures longer lifespan and reduces downtime. How do I pick the right undercarriage parts? Match the parts to your machine’s model and specifications. Check the manufacturer’s guidelines for size, material, and load capacity. Harsh working conditions need heavy-duty parts made from high-grade steel. Confirm compatibility with your excavator or bulldozer brand to avoid fitting issues. What causes undercarriage parts to wear out fast? Dirt, rocks, and debris accelerate wear. Improper track tension or operating on uneven surfaces adds stress. Lack of lubrication or ignoring small damages leads to bigger problems. Clean tracks regularly and inspect parts for cracks or misalignment. When should I replace sprockets or idlers? Look for uneven tooth wear on sprockets or visible cracks. Worn idlers cause track sagging or unusual noises during operation. Delaying replacements risks damaging the entire undercarriage system. Replace these parts early to prevent costly repairs. Do these parts work with different machine brands? Many aftermarket parts are designed for cross-brand compatibility. Verify dimensions and specifications match your equipment. Reputable suppliers provide detailed charts to confirm fitment. Universal parts are available but prioritize quality to ensure reliability. Proper care and timely replacements keep machinery running smoothly. Use genuine or certified parts to maintain performance.

(Factory Construction Machinery Parts Excavator Undercarriage Parts Excavator Bulldozer Spare Parts Sprocket Idler Track Roller)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Wholer Excavator Undercarriage Parts E200B Bottom Roller For All

High Quality Customizable Bucket Thumb Hydraulic Excavator Construction Machinery Attachments

OEM Factory excavator Quick Coupler Jc* 3cx Dx

Excavator Spare Part Alloy Steel Casting Standard Bucket Tooth SY100 For Mini Excavator