PRODUCT PARAMETERS

Description

Introduction to towed Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module)

Specification of Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module

This throttle electric motor component is built for CATERPILLAR 330B excavators. It makes certain precise control of engine rate for smooth procedure. The component matches OEM standards. It fits straight right into existing systems without modifications. Voltage ranking is 12V/24V. Present draw stays stable under heavy lots. Housing uses reinforced light weight aluminum alloy. This shields internal parts from dust, moisture, and resonances. Interior circuitry is shock-resistant. It takes care of temperature level arrays from -30 ° C to 85 ° C. Connectors are corrosion-resistant. They keep solid electrical contact in damp problems.

The component adjusts throttle feedback immediately. It communicates with the excavator’s ECU. Signal accuracy ensures fuel effectiveness. Engine power result stays constant during lengthy jobs. Wear-resistant equipments reduce mechanical failure dangers. Carbon brushes last longer than typical models. Substitute periods extend by about 30%. Examining consists of 500-hour endurance cycles. Each unit undertakes voltage surge checks. Performance metrics meet CATERPILLAR’s factory specifications.

Installment needs standard devices. Electrical wiring follows color-coded tags. Compatibility covers both older and reconditioned 330B models. Upkeep involves regular connector cleaning. No software program updates are needed. The layout avoids overheating. Thermal sensors activate automated closure if temperature levels exceed limitations. This shields the component and engine from damages.

Stringent quality control ensures zero issues. Distributors make use of ISO-certified production procedures. Third-party labs confirm toughness. The module comes with a 12-month service warranty. Support consists of technological diagrams and troubleshooting guides. Mass orders ship with safety packaging. Inventory matches worldwide security requirements.

This throttle electric motor module decreases downtime. It maintains excavators performing at peak efficiency. Operators notification smoother velocity. Gas intake remains reliable. The component operates in mining, construction, and heavy-duty settings. Dependability is proven in extreme problems. It stands up to chemical exposure and hefty influences. Supply schedule meets immediate fixing needs. Customer support assists with part number confirmation. Rates reflects affordable sector prices. Long-term usage lowers total upkeep prices.

(Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module)

Applications of Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module

The Caterpillar 330B throttle electric motor module is a crucial part for preserving the efficiency of excavators. It regulates engine speed instantly. This guarantees smooth operation throughout jobs like excavating, lifting, or moving materials. The module readjusts throttle settings based on work demands. This aids operators handle power successfully without hand-operated input.

One essential application is enhancing fuel efficiency. The module maximizes engine RPM to match the necessary power outcome. This decreases unneeded gas consumption during lighter jobs. Reduced gas use cuts running expenses with time. It likewise decreases engine wear by staying clear of continuous high-speed procedure.

The throttle electric motor component sustains specific control in heavy-duty atmospheres. It maintains consistent engine response throughout facility operations. This is important for jobs needing stable power, such as trenching or grading. Operators experience less delays brought on by unstable engine habits. Workflow keeps foreseeable, enhancing performance on task sites.

Sturdiness is an additional emphasis. The module is developed to hold up against harsh problems like dust, wetness, and resonance. Its tough style ensures reliability in building, mining, or forestry settings. This lowers downtime caused by part failing. Regular upkeep comes to be less complex, as the component integrates seamlessly with the excavator’s diagnostic systems.

Compatibility with other systems is a major benefit. The module deals with hydraulic controls, sensing units, and the primary control system. This combination permits real-time changes for optimal maker performance. Technicians can quickly recognize problems making use of onboard diagnostics. Repair services or substitutes are streamlined, decreasing equipment still time.

Safety advantages are likewise noteworthy. Steady throttle control prevents abrupt engine rises or drops. Operators avoid unexpected activities during fragile jobs. This protects both the devices and employees nearby.

Replacing worn or damaged throttle electric motor components restores factory-level accuracy. Older systems may trigger unpredictable throttle habits, causing inadequacy or safety and security threats. Installing a real Caterpillar 330B component makes sure compatibility and performance. It prolongs the excavator’s lifespan while keeping operational requirements.

The component contributes in exhausts management. By enhancing burning, it assists fulfill ecological laws. This is increasingly essential in areas with rigorous emission criteria. Minimized exhaust output supports sustainable operations without compromising power.

Company Introduction

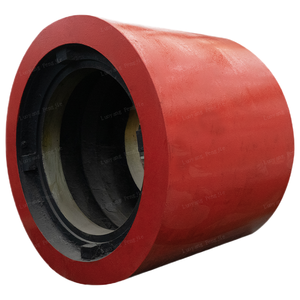

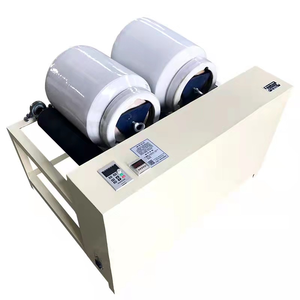

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module

The throttle motor module controls engine speed in the CATERPILLAR 330B excavator. It adjusts fuel flow based on operator input. This part ensures smooth acceleration and consistent power during digging or lifting. Replacing a faulty module restores precise throttle response.

This module fits only the CATERPILLAR 330B model. Confirm your excavator’s serial number matches the part specifications. Using incompatible modules risks engine damage or poor performance. Always verify compatibility with the supplier before purchasing.

A failing throttle motor module causes unresponsive throttle controls. The engine might idle roughly or stall unexpectedly. Speed fluctuations during operation signal potential module issues. Check electrical connections first. If problems persist, test or replace the module.

Installation requires basic mechanical skills. Disconnect the battery to avoid electrical hazards. Remove the old module and connect the new one following wiring diagrams. Secure all bolts and test the system before resuming work. Hire a certified technician if unsure.

Clean the module regularly to prevent dirt buildup. Inspect wiring for wear or corrosion. Avoid exposing the module to excessive moisture or heat. Replace damaged connectors immediately. Routine checks extend the module’s lifespan and reduce breakdown risks.

(Excavator Spare Parts for CATERPILLAR 330B Throttle motor Module)

REQUEST A QUOTE

RELATED PRODUCTS

E200B 1U3202 RC A1 Bucket Teeth 53103205 U3202RC Excavator Rock Bucket Tooth for Undercarriage Parts

Digger Attachments excavator Rotating Grabber For

High-quality Forged Track Idler Front Idler Excavator Undercarriage Spare Parts for LiuGong 220/230/922D/925D

Dragline Excavator Custom main drive Large Module Spur Gear Shaft Forged Transmission Spline Gear Shaft