PRODUCT PARAMETERS

Description

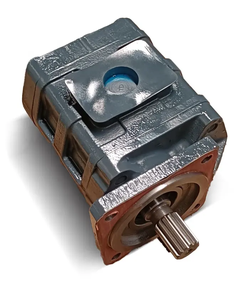

Introduction to towed Excavator Rollers Spare Parts track roller

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Excavator Rollers Spare Parts track roller refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Excavator Rollers Spare Parts track roller

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Excavator Rollers Spare Parts track roller)

Specification of Excavator Rollers Spare Parts track roller

Excavator track rollers are important components. They aid the excavator relocation efficiently. These rollers bring the equipment’s weight. They roll along the track chain. This movement occurs over the ground surface. Dust and rocks are anywhere. The rollers deal with constant pressure and wear. Good quality rollers are important. They keep the tracks straightened correctly. They stop the tracks from derailing. They also reduce resonance during operation. This makes the equipment much easier to control. It makes the driver much more comfortable as well.

These rollers are constructed challenging. They are normally made from hardened steel. This steel is really solid. It can take care of heavy influences. It stands up to obtaining crushed. The surface is typically heat-treated. This makes the outer layer added difficult. It battles against abrasion from dirt and rocks. Good rollers have actually secured bearings inside. These seals keep grease in. They keep dirt and water out. This lubrication is important. It stops the roller from overheating. It stops the bearings from taking up. Secured bearings need much less maintenance. They last much longer.

Different excavator versions require different rollers. Dimension matters a great deal. The roller size must match the track chain. The width has to fit the track shoe. The mounting style is also essential. Rollers affix to the undercarriage framework. The screw pattern have to be correct. Constantly check your equipment’s specific design number. Make use of the maker’s specs. Obtaining the best part guarantees correct fit. It makes sure reputable efficiency.

Bad rollers trigger problems. Worn rollers create uneven track wear. They let the track sag or end up being loosened. This places additional strain on various other undercarriage components. Gears and idlers wear out quicker. Fuel effectiveness declines. The machine may not move right. Changing rollers in a timely manner conserves cash. It stops larger, more expensive repair work later. It keeps your excavator efficient. Select rollers understood for sturdiness. Seek top quality products and good sealing. Don’t simply select the cheapest option. Excellent rollers are a smart financial investment. They maintain your device running well.

(Excavator Rollers Spare Parts track roller)

Applications of Excavator Rollers Spare Parts track roller

Excavator track rollers are tough parts. They rest inside the track chain assembly. Their work is crucial. They lug the equipment’s weight. This is heavy work. They likewise lead the track chain efficiently over the framework. This maintains the track relocating correctly. Without excellent rollers, the excavator can not move well.

These rollers deal with continuous tension. They roll over harsh ground daily. Dust, rocks, and particles struck them hard. They birth the complete tons of the machine. Friction uses them down with time. Water and mud cause deterioration. This severe atmosphere suggests rollers break. Changing worn rollers is necessary upkeep.

Utilizing high-grade replacement track rollers issues. They restore the excavator’s security. Great rollers maintain the track lined up properly. This prevents the track from sliding off. It quits uneven endure other parts. Smooth rolling lowers stress on the drive electric motor. This saves fuel. The maker relocates a lot more efficiently.

Reputable rollers imply less device downtime. Broken rollers quit working. Changing them quickly gets the excavator back digging. Strong rollers take care of hefty lots securely. They prevent abrupt failures. Operators really feel even more confident. The device carries out accurately on any type of work site.

Selecting the best spare part is crucial. The roller has to match the excavator design exactly. Correct size and specs are important. An excellent fit makes certain everything works together. It shields the gears and idlers. It expands the life of the entire undercarriage system. Buying real or top notch aftermarket rollers pays off. It stays clear of pricey repair work later. It maintains the equipment efficient longer.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Excavator Rollers Spare Parts track roller

What exactly do excavator track rollers do?

Track rollers carry the weight of the excavator. They roll along the inside of the track chain. This keeps the tracks moving smoothly over the ground. They prevent the track links from dragging directly on the undercarriage frame. Good rollers are vital for stable machine operation.

How do I know my track rollers need replacing?

Look for visible damage like cracks or deep gouges. Listen for unusual grinding or squealing noises from the undercarriage. Check for excessive wobble when you try to shake the roller. Notice if the tracks seem uneven or sagging. These signs mean the rollers are worn out. Replace them quickly to avoid more damage.

How do I pick the right replacement track roller?

You must match the roller to your specific excavator model. Find the exact part number from your machine’s manual. Check the old roller itself for stamped numbers. Get the roller size correct. The inner diameter and width must fit your track chain perfectly. Using the wrong roller causes fast wear and poor performance.

How long should a new track roller last?

Roller life depends heavily on how you use the machine. Harsh conditions like rocks and mud wear them faster. Regular cleaning helps remove abrasive dirt. Proper track tension is also critical. Expect several thousand hours of use from quality rollers. Inferior parts wear out much faster.

Can I replace a track roller myself?

Yes, experienced mechanics often do this job. You need the right tools like heavy jacks and possibly a torch. Follow the service manual steps exactly. Removing the track is usually necessary. Ensure the new roller is greased properly before installing it. Mistakes can damage the undercarriage. Get professional help if unsure.

(Excavator Rollers Spare Parts track roller)

REQUEST A QUOTE

RELATED PRODUCTS

PC30 Mini excavator undercarriage parts 20S-30-72120 front idler good quality

Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

Excavator spare parts 469-5312 Accessories C7 LINER KIT engine 336D2 LINER KIT C7 rebuild kit 4695312 1903526 190-3526 For CAT