PRODUCT PARAMETERS

Description

Introduction to towed Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts)

Specification of Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts

Carrier rollers are critical excavator undercarriage components. These rollers sustain the entire device’s weight. They direct the track chain smoothly. Provider rollers rest in between the idler and the gear. They maintain the track chain straightened appropriately throughout procedure. Proper placement protects against derailments and decreases wear.

Sturdy building demands solid carrier rollers. Quality rollers handle immense stress and shock loads. They withstand constant impacts from rocks and unequal ground. Rollers are developed challenging. They include hardened steel shafts and durable outer cases. Secured bearings are crucial inside. Excellent seals maintain dust, water, and debris out. This secures the bearings. Secured bearings last much longer. Roller flanges are necessary too. These flanges prevent the track chain from sliding off sidewards.

Material top quality issues greatly. State-of-the-art steel alloys stand up to wear and deformation. Heat treatment procedures make the steel harder. Harder steel surfaces stand up to abrasion much better. Precision machining makes certain smooth rotation. Smooth turning lowers rubbing. Much less rubbing indicates less heat and power loss. Reliable rollers contribute to decrease fuel intake with time.

Routine evaluation of service provider rollers is required. Look for noticeable damage like fractures or dents. Listen for unusual grinding sounds during operation. Too much sound frequently signals bearing failing. Used rollers trigger uneven track wear. They additionally strain various other undercarriage components like idlers and sprockets. Changing used rollers promptly prevents bigger troubles. It stays clear of costly repair work later on. It also keeps the machine stable and safe.

Picking the appropriate provider roller is crucial. Match the roller to your particular excavator version. Ensure precise measurements and placing requirements. Authentic OEM parts or high-grade aftermarket rollers are trusted alternatives. Quality rollers keep optimum track tension. They guarantee steady device activity on laborious websites. Excellent rollers significantly extend the undercarriage system’s overall life. They decrease device downtime. This saves cash and maintains projects on time.

(Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts)

Applications of Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts

Excavator provider rollers are essential parts of the undercarriage. They sustain the excavator’s weight and guide the track chain. Their work is crucial for smooth activity and stable procedure. These rollers handle consistent anxiety and severe conditions. They are developed hard for sturdy job.

Provider rollers are essential in earthmoving work. They keep the excavator secure while excavating trenches or relocating soil. Great rollers protect against track derailment and uneven wear. This means less downtime and lower fixing costs. Operators count on them for regular efficiency at work site.

Mining procedures require extreme longevity. Provider rollers right here face rock, particles, and heavy tons. They need to withstand constant resonance and influence. Robust rollers extend the equipment’s working life. They assist maintain efficiency popular mining environments.

Road building and construction uses excavators for grading and structure work. Provider rollers provide security on irregular ground. They make certain exact maker control. This is crucial for attaining exact qualities and slopes. Trustworthy rollers prevent unanticipated stops throughout important jobs.

Demolition websites present one-of-a-kind threats. Falling particles and unsteady surfaces examine the underercarriage. Strong service provider rollers keep equipment flexibility. They permit risk-free navigation through debris. Operators need this dependability for effective demolition development.

Extreme atmospheres like quarries or muddy websites speed up wear. Provider rollers resist abrasion and deterioration. They protect the track frame and various other parts. Quality rollers are a smart financial investment. They reduce long-lasting upkeep costs. Choosing the right carrier roller issues for any kind of excavator application.

Company Introduction

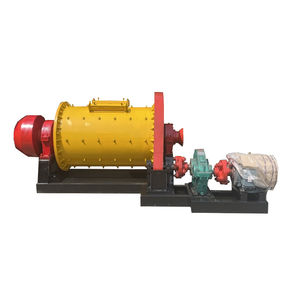

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts

What exactly do carrier rollers do?

Carrier rollers support the excavator’s track chain. They keep the track aligned correctly on the upper frame section. This reduces wobbling and bouncing during operation. Smooth track movement is essential for stable machine performance.

How can I tell if my carrier rollers are worn out?

Look for visible cracks or deep grooves on the roller surface. Listen for unusual grinding or squeaking noises from the undercarriage. Check for excessive track sag between the rollers. Uneven wear patterns on the track links also point to roller problems. Leaking grease seals mean the roller bearings are failing.

What’s important when choosing new carrier rollers?

Match the exact part number from your machine’s service manual. Confirm compatibility with your excavator model, brand, and series. Consider the material quality. Steel rollers last longer under heavy loads. Check the bearing seal design. Good seals keep dirt and water out. This extends roller life significantly.

Can I make my carrier rollers last longer?

Yes, regular cleaning helps a lot. Remove packed mud and debris from the undercarriage often. Inspect rollers weekly for early damage signs like scratches or grease leaks. Avoid running the tracks over sharp rocks or debris piles unnecessarily. Proper track tension adjustment prevents extra strain on all rollers.

When should carrier rollers be replaced?

Replace them when the outer surface shows heavy flaking or severe wear. Replace rollers immediately if the bearings feel rough or seize up. Significant grease leakage requires replacement. Replace rollers showing cracks or major dents. Don’t wait for rollers to fail completely. Bad rollers damage other expensive undercarriage parts like the track chain and sprockets.

(Excavator Carrier Roller Excavator Construction Machinery Undercarriage Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Excavator Spare Part Alloy Steel Casting Standard Bucket Tooth SY100 For Mini Excavator

Customized Good Various excavator Track Assembly Track Shoe Pad excavator spare parts For

High Quality Used Original Komatsu PC300 Excavator Components Heavy Machine Kyb Gearbox Engine Plc Motor Gear