PRODUCT PARAMETERS

Description

Introduction to towed 2025 new technology Doosan excavator used hydraulic hammer,rock breaker

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.2025 new technology Doosan excavator used hydraulic hammer,rock breaker refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed 2025 new technology Doosan excavator used hydraulic hammer,rock breaker

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(2025 new technology Doosan excavator used hydraulic hammer,rock breaker)

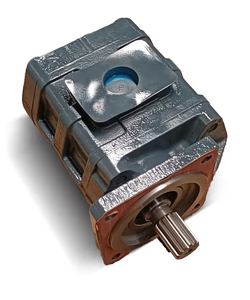

Specification of 2025 new technology Doosan excavator used hydraulic hammer,rock breaker

The 2025 Doosan excavator hydraulic hammer, a rock breaker, fits numerous Doosan excavator designs. This device is developed difficult. It takes care of demanding rock breaking jobs easily. The hammer delivers strong effect energy. This power effectively appears hard products. Operators see increased efficiency on website.

The style utilizes advanced hydraulic modern technology. This ensures smooth operation. The hammer functions well with the excavator’s hydraulic system. Power delivery corresponds. Performance remains trustworthy during long job hours. The hammer features a resilient steel housing. Strong internal components stand up to hefty impacts. This hammer lasts a very long time. Maintenance requirements are reduced. Special seals keep dust out. This shields crucial elements.

Driver convenience is necessary. The hammer design decreases vibrations. This decreases operator tiredness. Sound degrees are handled. The work environment stays far better. Transforming in between add-ons is quickly. The hammer attaches utilizing a conventional quick coupler. This conserves important time. Arrangement is straightforward. The hammer uses precise control. Operators can readjust impact pressure. This matches the particular task need. Precision enhances. Material waste decreases.

Security features are incorporated. An automated shut-off avoids damage. This happens if pressure drops too reduced. The system safeguards itself. Overheating dangers are reduced. Service factors are convenient. Routine checks are straightforward. Downtime is kept reduced. This hammer is a smart option for serious rock breaking. It brings power and dependability. Efficiency fulfills high assumptions.

(2025 new technology Doosan excavator used hydraulic hammer,rock breaker)

Applications of 2025 new technology Doosan excavator used hydraulic hammer,rock breaker

Doosan’s 2025 excavators are constructed hard. They take care of requiring jobs. One vital tool is the hydraulic hammer, likewise called a rock breaker. This effective add-on adjustments just how hard tasks get done. It breaks points apart successfully.

Demolition staffs count on these hammers. Old buildings need ahead down. Concrete slabs and structures are hard. The hydraulic hammer smashes them successfully. It attaches appropriate to the excavator arm. Operators control it precisely from the taxi. This is safer than older methods. Workers remain farther from falling debris. It quickens site clearing up as well.

Mining and quarrying face acid rock daily. Exploration and blowing up require time. They are in some cases also disruptive. The hydraulic hammer breaks rock directly. It fits on the excavator conveniently. Operators can break rocks at the pit face. They can size rock right at the crusher. This reduces double-handling product. It keeps manufacturing relocating smoothly. The hammers are built to last in rough problems.

Building websites often strike unexpected rock. Digging trenches or foundations stops. Generating an unique hammer device expenses money. It wastes time. A Doosan excavator with a placed hydraulic hammer addresses this. Operators button from bucket to hammer quickly. They damage the rock today. Work proceeds practically right away. This saves substantial project time and cost.

Roadway job regularly needs rock breaking. Developing secure embankments or leveling ground requires it. Repairing existing roads commonly suggests breaking old sidewalk. The excavator’s reach and the hammer’s power are excellent. Operators placement the hammer precisely where needed. They break rock or sidewalk without destructive nearby locations. This accuracy is vital in tight spaces. It makes the work cleaner and faster.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 2025 new technology Doosan excavator used hydraulic hammer,rock breaker

What model Doosan excavators work with the 2025 hydraulic hammer?

Most new Doosan excavators fit the hammer. Check the machine’s weight class. Match this to the hammer size. Doosan provides specific compatibility charts. Your dealer confirms the best fit for your model. Don’t guess.

How hard is installing the hydraulic hammer?

Installation is straightforward. You need the right mounting bracket. Connect the hammer’s hydraulic lines to the excavator’s auxiliary ports. Ensure all connections are tight. Test the hammer controls before starting work. A qualified technician does this quickly.

What maintenance does the hydraulic hammer need?

Regular maintenance is essential. Grease the hammer bushings daily. Check hydraulic oil levels often. Inspect the tool bit for wear. Replace worn bits immediately. Follow the service schedule in the manual. Proper care prevents expensive repairs.

Does the hammer damage my excavator?

Using the hammer correctly avoids damage. Never exceed the machine’s recommended hydraulic flow and pressure. Use the hammer only for suitable materials like rock or concrete. Avoid “blank firing” (hitting air). Correct operation protects the excavator’s hydraulic system.

How do I operate the hydraulic breaker safely?

Safety is critical. Wear proper protective gear always. Ensure the work area is clear of people. Position the excavator stable and level. Keep the tool bit perpendicular to the work surface. Don’t use the hammer for prying or lifting. Watch for flying debris.

(2025 new technology Doosan excavator used hydraulic hammer,rock breaker)

REQUEST A QUOTE

RELATED PRODUCTS

E320 E312 E307 E200B E180 E345 E325 Excavator operator Cabin seat Driving Cabin seats for Caterpillar Dedicated excavator chair

Excavator spare parts 306-9144 engine G3516 G3516B G3520B THROTTLE GP 3069144 For Caterpillar

China Professional 331 320 Undercarriage Parts For Excavator

Excavator Spare Parts Track Roller

Excavator Spare Parts Diaphragm for Construction Machinery