PRODUCT PARAMETERS

Description

Brief introduction of The factory customizes small energy-saving ball mill grinding equipment

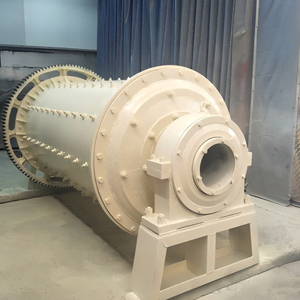

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. The factory customizes small energy-saving ball mill grinding equipment refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of The factory customizes small energy-saving ball mill grinding equipment

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(The factory customizes small energy-saving ball mill grinding equipment)

Specification of The factory customizes small energy-saving ball mill grinding equipment

The factory offers customized small energy-saving ball mill grinding equipment designed for efficient material processing. This equipment handles various materials, including minerals, ceramics, and chemicals. It suits small-scale production needs while prioritizing energy efficiency and durability. The compact design saves space and reduces operational costs.

The ball mill uses advanced energy-saving technology to cut power consumption by up to 30% compared to traditional models. It operates quietly and produces minimal vibration. The grinding chamber is built with wear-resistant materials, ensuring long service life even under heavy use. The inner lining and grinding media can be customized based on material hardness and processing requirements.

Customization options include adjusting drum size, motor power, and rotation speed. The drum capacity ranges from 50 liters to 1,000 liters. Motor power options vary between 5.5 kW and 55 kW. Rotation speed is adjustable from 20 rpm to 60 rpm for precise control over grinding fineness. The equipment supports both dry and wet grinding methods.

A robust steel frame provides stability during operation. The user-friendly control panel allows easy adjustment of operational parameters. Safety features include overload protection and emergency stop functions. The equipment meets international safety standards and undergoes rigorous quality testing before delivery.

The grinding process is optimized for uniformity and consistency. Particle size distribution can be fine-tuned to meet specific project needs. The ball mill works well for both batch and continuous production. Maintenance is straightforward, with easily accessible components for cleaning or replacement.

Technical specifications include a voltage range of 380V to 415V and three-phase power supply. The equipment is compatible with auxiliary components like cyclones or dust collectors. Optional features include automated feeding systems and real-time monitoring sensors. These additions improve productivity and reduce manual intervention.

Applications span mining, construction materials, paints, and pharmaceuticals. The ball mill handles materials with Mohs hardness below 8. It processes materials into powders as fine as 10 microns. Delivery timelines depend on customization complexity, with standard models shipped within 3 weeks.

(The factory customizes small energy-saving ball mill grinding equipment)

Applications of The factory customizes small energy-saving ball mill grinding equipment

The factory customizes small energy-saving ball mill grinding equipment for various industrial needs. This equipment processes raw materials into fine powders. It works in mining, ceramics, chemical production, and construction materials. The ball mill crushes and grinds materials using steel balls inside a rotating drum. This method ensures even particle size distribution.

Industries choose this equipment for its adaptability. The factory tailors each unit to fit specific operational demands. Adjustments include drum size, rotation speed, and material compatibility. Users handle minerals, cement, ores, or ceramics without issues. The design focuses on energy efficiency. It reduces power use by up to 30% compared to traditional mills. Lower energy costs benefit businesses long-term.

Durability is a key feature. The mill uses high-quality steel and wear-resistant parts. This minimizes maintenance needs and extends service life. Operators save time and money on repairs. The compact size suits small to medium production facilities. It fits into existing workflows without major layout changes.

Environmental impact matters. The energy-saving design cuts carbon emissions. Businesses meet sustainability goals while maintaining productivity. Safety features protect workers. Automatic shutoff systems prevent overheating. Emergency stops add another layer of protection.

The equipment supports precise control over grinding fineness. Adjustable settings let users achieve desired material consistency. This is critical in industries like pharmaceuticals or advanced ceramics. Consistent product quality improves end-user satisfaction.

Remote monitoring options are available. Sensors track performance metrics in real time. Operators detect issues early and optimize processes. This reduces downtime and boosts efficiency.

Cost-effectiveness makes the equipment a practical investment. Lower energy use, minimal maintenance, and long lifespan ensure quick returns. The factory offers post-purchase support. Technical assistance and spare parts keep operations smooth.

The ball mill adapts to emerging industry trends. It handles new materials and evolving production standards. Businesses stay competitive without frequent equipment upgrades. Reliability and flexibility make it a core asset in modern manufacturing.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of The factory customizes small energy-saving ball mill grinding equipment

What types of customization do you offer for small energy-saving ball mills? The factory provides tailored solutions based on client needs. Modifications include adjusting drum size, motor power, and rotational speed. Materials for liners and grinding media can be chosen for specific tasks. Control systems are upgraded for automation or manual operation. Custom branding and color options are available for company identity.

How does the energy-saving feature work in these ball mills? The design reduces power use through optimized mechanical structures and efficient motors. Energy loss is minimized during grinding. Advanced insulation keeps heat inside the drum, cutting reheating needs. Lower energy consumption saves operational costs. Tests show up to 30% less electricity use compared to standard models.

What materials can these ball mills grind? They handle metals like gold and copper ores. Non-metallic materials include cement, ceramics, and quartz. Wet or dry grinding modes suit different materials. Hardness limits apply based on liner and grinding media choices. The factory advises clients on material compatibility before purchase.

How often does the equipment need maintenance? Routine checks are recommended every 200 operating hours. Lubrication of bearings and gears is done monthly. Worn liners or media should be replaced when thickness drops by 30%. Annual motor inspections ensure long-term performance. Maintenance schedules vary with usage intensity and material abrasiveness.

What is the typical delivery time after ordering? Standard orders ship within 3–4 weeks. Custom designs take 5–6 weeks due to extra production steps. Delays happen if rare materials or complex parts are needed. The factory provides updates if timelines change. Express shipping options are available for urgent requests.

(The factory customizes small energy-saving ball mill grinding equipment)

REQUEST A QUOTE

RELATED PRODUCTS

Small 5t/h ball mill for gold mining cement clinker grind ball mill limestone

Low Energy Saving ball mill grinding cement grinding ball mill

Ball Mill Grinding Ball Rod for Ore/Rock 0.074mm 1/4/6/7L Small Wet/Dry Grinder Miller

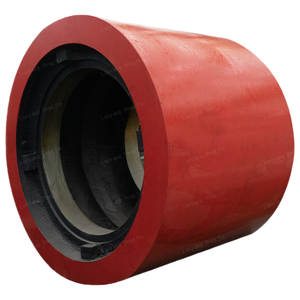

Metal Mine Ball Mill Liner Plate for Mining Machine Parts

Rolling Ring Tyre/big Riding Ring/ball Mill Ring Tyre Dryer Rotary Kiln Industrial Sprocket Transmission Gear Spare Parts