PRODUCT PARAMETERS

Description

Brief introduction of Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner

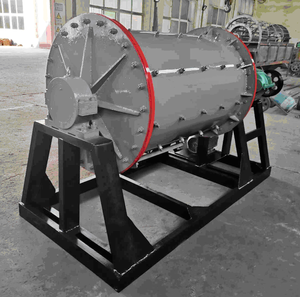

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner)

Specification of Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner

The Tiny Round Mill for Research Laboratory Grinding Equipment is developed for grinding and blending materials in gold handling and various other laboratory applications. It takes care of small example volumes, making it excellent for study and screening. The device makes use of a resilient liner made from high-grade wear-resistant products like rubber, ceramic, or steel. This liner shields the grinding drum, prolongs devices life, and improves grinding efficiency.

The ball mill has a compact framework with a capability ranging from 0.5 to 50 litres. It supports completely dry and damp grinding approaches. The motor power ranges 0.5 kW and 2.2 kW, making certain steady procedure for products of different firmness degrees. The turning speed changes from 50 to 300 RPM, permitting individuals to control bit dimension output. The grinding media, such as stainless steel or ceramic rounds, are chosen based on product compatibility.

The drum is constructed from robust steel, coated with the selected liner material. This prevents contamination and preserves example pureness. The equipment includes a straightforward control board with timers and rate settings. Safety functions cover overload security and emergency situation quits. The layout complies with laboratory security criteria.

This round mill fits tasks like grinding ores, minerals, and chemical substances. It is commonly utilized in metallurgy, geology, and products science labs. The little size saves room while delivering precise results. Upkeep is straightforward, calling for regular cleansing and lubrication.

The device operates on 220V or 110V power, adapting to different lab arrangements. Sound levels stay listed below 65 dB during use. Optional devices consist of extra liners, grinding media, and sample collection trays. The device ships fully put together, prepared for immediate usage after installment.

Gold processing applications take advantage of the liner’s abrasion resistance, minimizing downtime for substitutes. The grinding chamber seals securely to avoid leakages. Users can check progress with a transparent checking out home window on some designs. Technical assistance is readily available for fixing and optimization.

This ball mill balances efficiency and cost, meeting the needs of small laboratories. Its integrity makes certain consistent results in repetitive tests. Customized arrangements are possible based upon specific research study requirements.

(Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner)

Applications of Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner

Small sphere mills for lab grinding are essential devices in handling products like gold ores. These equipments take care of grinding jobs efficiently in small-scale settings. They match labs and research study facilities requiring exact control over particle size. The style concentrates on compactness and toughness. It permits very easy operation in restricted spaces without sacrificing performance.

The sphere mill’s lining plays an essential function in gold processing. It safeguards the internal drum from wear caused by rough materials. Liners made from top notch steel or rubber extend the device’s life expectancy. They additionally lower contamination throughout grinding. This is vital for precise analysis in gold extraction studies. The liner’s shape can influence grinding efficiency. Smooth surfaces help reduce energy intake while distinctive linings improve material agitation.

Laboratory service technicians utilize these mills for sample prep work. They grind ore samples to great powders for chemical or physical screening. Consistent particle size makes certain reputable results in assays. Adjustable turning speeds let users personalize grinding intensity. Timers automate the process, downtime for various other tasks. This versatility makes the mill perfect for varied research demands.

Gold handling requires rigorous hygiene to stay clear of cross-contamination. The mill’s sealed design avoids material leakage. Easy disassembly simplifies cleansing between batches. Corrosion-resistant materials guarantee long life despite having regular use. These functions make it a sensible selection for metallurgical laboratories.

Tiny sphere mills also serve instructional objectives. Colleges utilize them to show mineral handling principles. Pupils acquire hands-on experience with devices imitating industrial-scale operations. The equipment’s simplicity help in understanding core mechanics.

Operators appreciate the low maintenance requirements. Regular lubrication and part inspections maintain the mill running efficiently. Substitute liners are economical and extensively offered. This reduces downtime and lasting prices.

Safety and security features include overload defense and secure locking lids. These protect against mishaps during high-speed turning. Noise reduction modern technology creates a quieter lab setting.

The small ball mill adapts to varied grinding jobs beyond gold handling. It manages ceramics, chemicals, and structure materials. Its flexibility makes it a staple in laboratories worldwide.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner

What is the purpose of the liner in a small ball mill for gold processing? The liner protects the inner chamber of the ball mill from wear caused by grinding materials. It ensures the grinding process stays efficient by maintaining the mill’s shape. The liner also reduces contamination of processed gold by separating raw materials from the mill’s metal body. Regular inspection of the liner prevents unexpected damage during operation.

What materials are lab ball mill liners made of? Liners are typically made from stainless steel, rubber, or ceramic. Stainless steel offers high durability for heavy grinding tasks. Rubber liners reduce noise and are ideal for wet grinding processes. Ceramic liners suit applications requiring minimal contamination. The choice depends on the specific gold processing needs and material hardness.

How do I maintain the liner of a laboratory ball mill? Clean the liner thoroughly after each use to remove residue. Check for cracks or uneven wear regularly. Replace the liner if visible damage appears. Avoid using abrasive cleaning tools to prevent scratches. Lubricate the mill’s moving parts to reduce friction on the liner during operation.

How long does a ball mill liner last in gold processing? Liner lifespan varies based on material hardness and usage frequency. Stainless steel liners last several months under normal lab conditions. Rubber and ceramic liners may need replacement sooner if used for abrasive materials. Consistent maintenance extends the liner’s service life. Monitor performance changes to decide replacement timing.

Can the liner be customized for specific lab grinding needs? Yes. Manufacturers often provide customization for liner size, shape, and material. Custom liners improve grinding efficiency for unique gold ore types or sample sizes. Specify requirements like thickness or groove patterns to match your lab’s workflow. Custom options ensure compatibility with specialized grinding processes.

(Small Ball Mill For Laboratory Grinding Machine Ball Mill Gold Processing Liner)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Ball Mill Mineral Grindingfor Dry Wet Production Line – MineralProcessing

Ball Mill 6 Ball Mill Parts Gear Aluminum Powder Ball Mill 1200*4500

Customized Wear-resistant Plate Durable Ball Mill Liner For Mining

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

Double chamber ball mill dry beneficiation marble ore aluminum ash production line