PRODUCT PARAMETERS

Description

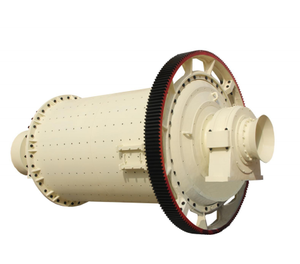

Brief introduction of hot ball mill grinding machine / slag / ore / industrial ball mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. hot ball mill grinding machine / slag / ore / industrial ball mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of hot ball mill grinding machine / slag / ore / industrial ball mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(hot ball mill grinding machine / slag / ore / industrial ball mill )

Specification of hot ball mill grinding machine / slag / ore / industrial ball mill

The warm ball mill grinding machine procedures materials like slag, ore, and industrial minerals effectively. It works by rotating a cyndrical tube loaded with grinding media– steel rounds or ceramic beads. The machine crushes and grinds raw materials into fine powders. This process matches high-temperature settings, making it excellent for heat-treated slag or ore decrease. The cylinder is constructed from heavy-duty steel for toughness. It takes care of temperature levels up to 300 ° C without shedding structural honesty.

The grinding chamber can be found in dimensions from 1 to 5 meters in size. Bigger chambers raise capability yet need more power. Motors range from 50 to 500 kW, depending on the version. Variable-speed drives let users readjust turning for various products. A typical machine runs in between 15 and 30 RPM. Reduced speeds develop coarser particles. Higher rates produce finer powders.

Linings inside the cylinder safeguard against wear. They are replaceable and made from manganese steel or rubber. Rubber linings minimize noise. Steel liners handle rough materials much better. The maker consists of a cooling system to take care of heat during long runs. Water or air cooling prevents overheating. This guarantees regular performance.

Feed dimensions differ from 25 mm to 50 mm. Outcome excellence ranges from 50 to 300 mesh. The equipment benefits completely dry and damp grinding. Damp grinding adds water to create a slurry. This decreases dirt and enhances mixing. Discharge methods include overflow or grate screens. Overflow matches finer outputs. Grate displays manage bit dimension.

Safety attributes consist of emergency situation stops, temperature sensors, and stress evaluates. Gain access to panels allow easy upkeep. Lubrication factors are positioned for fast maintenance. The base framework is welded steel for security. Anti-vibration pads lessen sound and movement.

Applications include cement manufacturing, steel mining, and chemical processing. It handles sedimentary rock, clinker, copper ore, and iron slag. Custom configurations support particular products. Options include additional insulation for high-heat jobs or corrosion-resistant finishings for acidic environments.

The maker requires regular look at bearings, liners, and motors. Cleaning after each run stops product accumulation. Extra components like seals and gaskets are commonly available. Educating handbooks and technological assistance aid drivers troubleshoot. Energy-efficient layouts reduced power use by approximately 20% contrasted to older versions.

(hot ball mill grinding machine / slag / ore / industrial ball mill )

Applications of hot ball mill grinding machine / slag / ore / industrial ball mill

Hot ball mill grinding machines handle tough jobs in many industries. These machines grind materials like slag, ore, and industrial waste into fine powders. They work well for high-temperature processes. This makes them ideal for heavy-duty tasks.

Slag processing is a key use. Steel plants produce slag as waste. The ball mill grinds this slag into small particles. The ground slag can then be reused in cement production or road construction. This cuts waste and saves costs. Metals trapped in slag are also recovered. This boosts recycling efforts.

Ore grinding is another major application. Mines extract ores like copper, iron, and gold. Raw ores often contain unwanted rock. The ball mill crushes ores into fine powder. This separates valuable metals from waste material. The process improves metal recovery rates. Consistent grinding ensures better quality for smelting or chemical processing. This machine handles hard ores efficiently.

Industrial ball mills adapt to many materials. Ceramics, cement, and chemicals rely on finely ground ingredients. The machine’s adjustable speed and temperature suit different products. For example, cement needs ultra-fine powder for strength. Chemicals require even mixing of reactive substances. The ball mill meets these needs. Factories use it for large-scale production. It reduces energy use compared to older methods.

Durability matters in harsh environments. Hot ball mills are built with heat-resistant metals. They run non-stop without breaking down. Maintenance is simple. Parts like grinding rollers are easy to replace. This lowers downtime. Operators control settings for precise results. Safety features prevent overheating or leaks.

Cost savings drive demand. Recycling slag cuts disposal fees. Efficient ore grinding raises profit margins. Industrial users produce more with less energy. The machine’s long lifespan adds value. Industries facing strict environmental rules benefit. Reduced waste and energy use meet sustainability goals.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of hot ball mill grinding machine / slag / ore / industrial ball mill

What is a ball mill grinding machine used for? It crushes and grinds materials like slag and ore into fine powder. The machine uses rotating drums filled with steel balls. The balls hit the material, breaking it down. This process is common in mining, cement, and chemical industries. It handles hard, abrasive materials efficiently.

How does a ball mill handle different materials like slag or ore? The machine adjusts rotation speed and ball size based on the material. Slag needs slower speeds to avoid overheating. Ore requires larger balls for harder impact. The drum’s lining can be changed to reduce wear from abrasive substances. Operators control feed size and grinding time for optimal results.

What maintenance does an industrial ball mill require? Regular lubrication of gears and bearings is essential. Check steel balls for wear and replace them if damaged. Inspect the drum lining for cracks or erosion. Clean the machine after use to prevent material buildup. Schedule professional inspections yearly to ensure parts work correctly.

Are industrial ball mills safe to operate? Safety features include emergency stop buttons and protective guards. Operators must wear gear like helmets and gloves. Avoid opening the drum during operation. Follow guidelines for load capacity to prevent overheating. Training is required to handle the machine safely.

How does a ball mill improve production efficiency? It grinds materials faster than manual methods. Uniform particle size ensures consistent product quality. The machine works continuously for large-scale operations. Energy-efficient models reduce power costs. Low maintenance needs cut downtime. This boosts output in industries like mining or cement manufacturing.

(hot ball mill grinding machine / slag / ore / industrial ball mill )

REQUEST A QUOTE

RELATED PRODUCTS

Manufacture super good quality Resistant Mining Spare Parts ball mill rubber lining

Overflow Ball Mill Mining Equipment Machine s/Grinding Mill/Rod Mill For Hematite, Iron Ore, Bentonite, Limestone, Cement

Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

High manganese casting ball mill parts mill impact liner plate and blow bar

Customized Various Sizes Rotary Kiln Spare Parts Cement Ball Mill Drive Large Casting Gears