PRODUCT PARAMETERS

Description

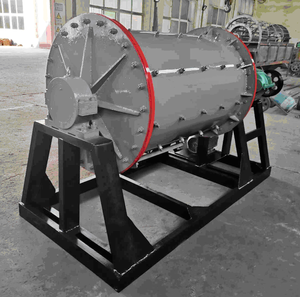

Brief introduction of Hot 2-10 tph Ball Mill For Grinding Iron Ore

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Hot 2-10 tph Ball Mill For Grinding Iron Ore refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Hot 2-10 tph Ball Mill For Grinding Iron Ore

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Hot 2-10 tph Ball Mill For Grinding Iron Ore)

Specification of Hot 2-10 tph Ball Mill For Grinding Iron Ore

The Warm 2-10 tph Round Mill is constructed for grinding iron ore efficiently. It manages abilities from 2 to 10 bunches per hour. The equipment fits mining and mineral handling procedures. Its design concentrates on longevity and efficiency. The sphere mill uses steel rounds to squash and grind ore right into great particles. The grinding procedure guarantees consistent fragment dimension for downstream handling.

The mill’s shell is made of top notch steel. It stands up to wear and effect throughout procedure. The internal lining usages manganese steel or rubber. This secures the covering from abrasion. The revolving drum is installed on a horizontal axis. It transforms at a regulated speed for ideal grinding. A high-torque electrical motor powers the system. The electric motor is paired with a gearbox for smooth turning.

Feed product gets in via one end. Ground ore departures via the various other. Fragment dimension is adjustable. Users regulate this by altering ball dimension or mill speed. The device includes a cooling system. This avoids getting too hot during continuous usage. Upkeep is straightforward. Gain access to factors allow quick assessment and component substitute.

Technical specs include a drum diameter of 1.5 to 2.5 meters. The size ranges from 3 to 4.5 meters. Overall weight ranges 8 and 15 bunches. Motor power starts at 18.5 kW for smaller sized designs. Larger units need approximately 75 kW. Running speed remains in between 20 and 30 RPM. The mill works with wet or completely dry grinding approaches.

Safety and security functions include emergency situation stop buttons and overload defense. Sensing units check temperature level and vibration. Operators receive alerts for uncommon conditions. The mill incorporates with existing handling lines. Installation needs a strengthened concrete foundation. Electrical links comply with industry criteria.

Optional upgrades consist of automated control systems. These adjust specifications for maximum performance. Dirt collection devices reduce airborne particles. Custom-made linings and round compositions are readily available. They expand service life for specific ore types. Regular lubrication makes sure smooth operation. Extra parts are widely available.

This sphere mill balances price and efficiency. It lessens downtime through reliable design. The device satisfies sector needs for iron ore processing. It adjusts to varying manufacturing demands without jeopardizing result high quality.

(Hot 2-10 tph Ball Mill For Grinding Iron Ore)

Applications of Hot 2-10 tph Ball Mill For Grinding Iron Ore

The hot 2-10 tph round mill is an essential device for grinding iron ore in numerous industries. This device crushes raw iron ore right into fine fragments. It functions well for processing materials in mining, metallurgy, cement, porcelains, and construction. Its style manages high temperatures during grinding. This makes it perfect for refining heated or dried ore.

In mining operations, the sphere mill breaks down large portions of iron ore. It turns them into consistent powder for simpler handling. The adjustable turning speed manages grinding efficiency. Customers obtain consistent fragment dimensions. This improves downstream processes like smelting or pelletizing. The maker functions non-stop. It satisfies high production demands without overheating.

Metallurgical plants utilize this round mill to improve iron ore focuses. It grinds ore to certain fineness degrees. This makes certain ideal chain reaction during removal. The long lasting building resists wear from abrasive products. Upkeep prices stay low. Operators save time on fixings.

Cement manufacturing facilities apply the ball mill to procedure iron ore ingredients. These additives enhance cement items. The mill blends materials uniformly. It takes care of both dry and a little wet ore. Temperature level control stops clumping. This keeps the grinding process smooth.

Ceramic producers count on the round mill for preparing iron-based pigments. The fine grinding produces consistent color distribution. The portable size fits little to medium production lines. Power usage continues to be reduced. Running prices stay convenient.

Building and construction projects make use of ground iron ore as a basic material for concrete or road bases. The ball mill generates the ideal appearance for mixing with other elements. Its easy procedure requires very little training. Configuration fasts. Production begins quick.

The warm 2-10 tph round mill adapts to various ore kinds. Difficult or soft ores grind efficiently. Users change setups for desired results. The durable develop guarantees lengthy life span. It performs dependably in harsh settings. Spare parts are simple to discover. Downtime remains minimal.

This tools suits little and moderate business. It balances capacity and cost. First investment is budget-friendly. Return on investment comes promptly. The machine satisfies security requirements. Operators face low threats throughout usage.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Hot 2-10 tph Ball Mill For Grinding Iron Ore

What is the capacity range of the Hot 2-10 tph Ball Mill? The Hot 2-10 tph Ball Mill handles grinding capacities between 2 and 10 metric tons per hour. This range suits small to medium-scale operations processing iron ore. The exact throughput depends on factors like ore hardness, feed size, and required fineness. Operators adjust parameters to match specific production needs.

How often does the ball mill need maintenance? Routine maintenance is essential for smooth operation. Key components like liners and grinding media wear down over time. Inspect the mill every 100-150 operating hours. Lubricate bearings and check bolts monthly. Replace worn parts immediately to avoid breakdowns. Proper upkeep extends the machine’s lifespan.

What safety features are included? The design prioritizes operator safety. Emergency stop buttons are installed on all sides. Guards cover rotating parts to prevent contact. Overload protection halts the mill if motor strain exceeds limits. Regular safety checks are mandatory. Follow guidelines in the user manual to minimize risks.

Can the mill handle other materials besides iron ore? Yes. The Hot 2-10 tph Ball Mill works for grinding various minerals like copper, gold, and limestone. Adjustments might be needed for material hardness or moisture content. Consult the manufacturer before switching materials. This ensures optimal performance and avoids damage.

How does the mill ensure consistent grinding quality? The drum’s rotation speed and grinding media size control particle uniformity. Classifiers screen output to separate fine and coarse particles. Coarse material returns for regrinding. Stable feed rates and regular monitoring maintain product consistency. Operators track fineness with periodic sampling.

(Hot 2-10 tph Ball Mill For Grinding Iron Ore)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Different Size End Cap Ball Mill Spare Parts Mining Machinery Ball Mill End Cover

Good factory Customized forged steel large diameter ring gear ball mill for drawing

Gear Shaft For Ball Mill Spline Gear Shaft Mining Spare Parts Gear Shaft For Gearbox

1230 1545 1830 2145 Stone Ball Mill Grinding Machine Ball Mill Machine Rolling Ball Mill Powder Grinder

Ball mill Spare parts ball mill liner accessories ball mill liner plate