PRODUCT PARAMETERS

Description

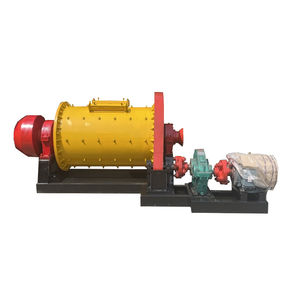

Brief introduction of High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding)

Specification of High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding

The high-grade ball mill version 3200 4500 is developed for effective grinding in sectors such as ceramics, glass, ore processing, and metalworking. It deals with materials with precision, guaranteeing consistent fragment dimension reduction. The machine features a robust structure constructed for durable operation. Its cylinder steps 3200 mm in diameter and 4500 mm in size, offering a big processing capacity. The rotational speed is set at 21 rpm, optimized for stabilizing grinding performance and energy consumption. The round mill operates making use of steel rounds or other grinding media, which roll inside the turning cyndrical tube to crush and mix products.

The covering is made from thick, high-strength steel plates bonded for durability. The lining usages wear-resistant products like manganese steel or rubber, expanding life span and reducing maintenance. The gearbox and motor are specifically matched to ensure smooth power transmission. The electric motor provides 400 kW, enabling stable operation under heavy loads. The maker includes an automated lubrication system to safeguard critical parts from wear.

Feed and discharge systems are designed for simple product flow. The feed bit dimension can rise to 25 mm, while the result excellence ranges from 0.074 mm to 0.4 mm. Individuals can change grinding time and media quantity to satisfy specific needs. The round mill sustains both dry and wet grinding techniques, adjusting to different material properties. Its modular layout streamlines installation and maintenance.

This design is extensively made use of in ceramic manufacturing for grinding glazes and raw materials. In the glass sector, it processes silica sand and feldspar. For ore beneficiation, it grinds minerals to prepare for removal. Metal powder manufacturing counts on its capability to accomplish consistent particle distribution. The maker’s reduced sound and resonance make certain a more secure office. Its energy-efficient design lowers operating expenses.

Extra parts like linings and equipments are easily available. Technical support is provided for troubleshooting and optimization. Custom-made arrangements are feasible based upon production requirements. The ball mill follows global safety and top quality standards. It integrates seamlessly into existing production lines. Normal upkeep checks are advised to sustain efficiency.

(High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding)

Applications of High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding

The top notch round mill 3200 4500 works as a key grinding tool across numerous markets. It takes care of materials like porcelains, glass, ore, and steels effectively. Its design makes certain reliable performance popular settings. The large drum dimension allows processing mass products quickly. This minimizes downtime and enhances productivity.

In the ceramic sector, the round mill grinds basic materials right into great powders. These powders develop the base for ceramic tiles, tableware, and hygienic products. Consistent bit dimension is essential for high quality. The mill’s precision grinding makes sure uniformity. For glass production, it crushes silica sand and various other parts. Smooth operation avoids contamination. This preserves the quality and strength of glass items.

Ore processing counts on the sphere mill to break down minerals. It extracts beneficial steels like copper and gold. The maker’s durable construction takes care of acid rocks without wear. Metal industries utilize it to create steel powders for alloys. These powders are crucial for vehicle and aerospace parts. The mill’s adjustable rate controls bit fineness. This meets strict market standards.

The ball mill’s structure consists of sturdy steel plates. A thick lining protects versus abrasion. This extends the equipment’s life expectancy. It uses sophisticated bearings to lessen friction. Energy usage stays reduced. Operators locate it very easy to keep. The design includes obtainable parts for quick fixings.

Security functions protect against accidents throughout procedure. Emergency quit buttons and overload protection are basic. Dust control systems maintain work areas tidy. This protects worker health and wellness. Noise degrees stay within secure limits. The mill incorporates with existing production lines. Customization alternatives are offered. Customers can choose lining materials or motor kinds.

Industries value the ball mill 3200 4500 for its versatility. It adapts to various products and grinding requirements. High performance and longevity make it an affordable remedy. Organizations see faster rois. The device sustains lasting techniques. It minimizes waste and energy usage. This straightens with modern-day ecological objectives.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding

1. What industries use the high-quality Ball Mill 32004500? The Ball Mill 32004500 works in ceramic, glass, ore, metal industries. It grinds raw materials, minerals, chemicals. Ceramic factories use it for clay. Glass plants grind silica. Mining processes metal ores. Factories adjust rotation speed for different materials. This flexibility makes it popular across sectors.

2. What materials can the Ball Mill 32004500 grind? It handles hard and soft materials. Ceramic powders, glass fragments, metal ores, cement work. The grinding chambers use steel or ceramic balls. These crush materials into fine particles. Moisture content or hardness do not limit performance. Users change ball sizes for desired fineness.

3. What features improve grinding efficiency? The mill has a robust structure. Wear-resistant liners reduce downtime. A high-capacity motor ensures steady power. Large processing capacity cuts energy use. Advanced design minimizes heat. Noise stays low during operation. Stability prevents vibrations. These features boost productivity.

4. How is maintenance managed? Regular checks are key. Lubricate bearings weekly. Inspect bolts monthly. Replace worn liners yearly. Clean the chamber after each batch. Check gear alignment quarterly. Follow the manual for part replacements. Proper care extends the machine’s lifespan.

5. Can the Ball Mill 32004500 be customized? Yes. Clients choose liner materials, motor power, control systems. Factories adjust dimensions for specific needs. Engineers help select settings for materials. Custom orders take 4–6 weeks. Support teams provide installation guidance. Spare parts are available globally.

(High quality Ball Mill 32004500 widely used in ceramic glass ore metal and other industries grinding)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Forged Steel Balls and liners For Ball Mill, Attrition Mill

Forging Cement Machinery Parts Rotary Kiln Ring Gears Ball Mill Large Diameter Ring Gears

Mini ball mill for coal

cement ball mill machine stone grinding with ball mill parts

heavy duty mining ball mill spare part 42CrMo steel hollow shaft