PRODUCT PARAMETERS

Description

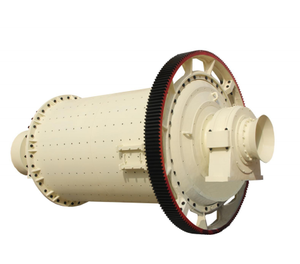

Brief introduction of High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for )

Specification of High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for

The High Quality 2TPH 900X3000 Round Mill (Design 0933) is built for grinding products in markets such as mining, cement, and chemicals. It manages approximately 2 lots per hour. The cylinder gauges 900mm in diameter and 3000mm in length. It utilizes steel balls to crush and grind resources right into great powder. The device deals with an electric motor and transmission to revolve the cyndrical tube. This makes sure steady procedure and effective grinding.

The sphere mill’s framework is basic. It makes use of thick steel plates bonded for sturdiness. The internal lining is wear-resistant. This minimizes upkeep demands. The maker supports completely dry and wet grinding. Individuals change the material fineness by controlling the grinding time or steel sphere dimension. It fits refining ores, cement clinker, silicates, and ceramics.

Installation is uncomplicated. The layout consists of a solid base structure. This reduces resonance during usage. The electric motor power matches the load demands. It saves power while preserving efficiency. Safety attributes avoid overheating or overloading. Operators can access components quickly for cleaning or fixings.

The 900X3000 ball mill operates in harsh environments. It withstands deterioration and wear. The steel spheres and cellular lining are exchangeable. This extends the machine’s life expectancy. It generates consistent bit dimensions. This fulfills high quality standards for commercial usage.

The equipment suits tiny to medium production lines. It stabilizes expense and performance. Customers benefit from low functional expenses. The small design conserves area. It incorporates efficiently with various other equipment. Technical assistance is offered for arrangement and troubleshooting.

This sphere mill is a sensible option for trusted material handling. It supplies steady outcome with very little downtime. The build top quality ensures lasting use. It meets the needs of services seeking economical, high-performance grinding solutions.

(High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for )

Applications of High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for

The high-grade 2TPH 900X3000 ball mill (model 0933) offers lots of sectors. It grinds materials right into great powders. This maker works well for mining operations. It refines ores like gold, copper, and iron. The grinding chamber deals with tough compounds successfully. Its design ensures consistent efficiency under heavy use.

Building products gain from this ball mill. It creates concrete, ceramics, and glass. The device blends basic materials uniformly. This creates consistent products for building jobs. The resilient framework reduces wear during lengthy grinding sessions. Upkeep stays simple, saving time and expenses.

Chemical sectors count on this devices. It refines chemicals into fine powders for responses. The sealed design protects against leakages. This keeps offices safe. The flexible rotation speed controls bit size. Customers achieve consistent results for different solutions.

Reusing plants utilize the 0933 round mill. It breaks down waste products like metal scraps or digital parts. The device recovers important steels from recycled items. Its energy-efficient electric motor decreases power intake. This sustains green procedures.

Small labs and workshops locate this sphere mill valuable. It handles smaller sized sets for checking new materials. The portable size fits restricted spaces. Operators readjust settings quickly for exact experiments. The equipment’s dependability makes certain exact data collection.

This sphere mill fits dry and damp grinding. Customers switch in between settings without headache. The durable steel construction withstands corrosion. This extends the machine’s lifespan. Components like linings and gears are replaceable. Downtime stays minimal during repairs.

Farmers and fertilizer manufacturers apply this tools. It grinds raw minerals right into nutrient-rich powders. The fine appearance boosts dirt absorption. Crop yields boost with equally mixed fertilizers. The equipment handles organic and artificial products.

Mining firms value the 900X3000 sphere mill for remote websites. It runs efficiently in harsh settings. The low vibration style lowers sound. Workers face fewer disruptions. Arrangement calls for standard training, making it obtainable for brand-new groups.

The 2TPH ability equilibriums speed and accuracy. It meets medium-scale production demands without straining systems. The inexpensive price fits budget-conscious buyers. Its versatility across markets makes it a functional investment.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for

What is the processing capacity of the High Quality 2TPH 900X3000 Ball Mill? The ball mill handles up to 2 tons of material per hour. It suits grinding ores, cement, and ceramics. The 900mm diameter and 3000mm length provide efficient grinding for medium-scale operations.

What materials can the 0933 Ball Mill process? It processes hard and brittle materials like quartz, granite, and metal powders. Wet or dry grinding modes are available. The machine adapts to different industries. Its structure prevents contamination during processing.

How does the 900X3000 Ball Mill ensure grinding efficiency? The rotating cylinder contains steel balls that crush materials through impact and friction. Speed and ball size are adjustable. This controls particle size. The design minimizes energy waste. It maintains stable performance over long runs.

What maintenance does the 0933 Ball Mill require? Check lubrication weekly. Replace worn parts like liners and gears promptly. Clean the machine after each use. Inspect bolts and belts monthly. Proper maintenance extends service life. Follow the manual for detailed schedules.

Is the 2TPH Ball Mill safe to operate? Safety features include overload protection and emergency stops. The sealed design reduces dust and noise. Operators must wear protective gear. Training is needed before use. Regular inspections prevent accidents. The machine meets industry safety standards.

(High Quality 2TPH 900X3000 Ball Mill, 0933 Ball Mill for )

REQUEST A QUOTE

RELATED PRODUCTS

High Efficiency Limestone Mine Ball Mill Ceramic Grinding Ball Mill For Stone Gold

Double chamber ball mill dry beneficiation marble ore aluminum ash production line

Whole : durable 400*600 600*800 900×1800 Ball Mill Mining Ball Mill

Rotary Kiln and Cement Ball Mill Spare Pasts Large Steel Spur Gear Wheel and Ring Gear Casting Girth Gear