PRODUCT PARAMETERS

Description

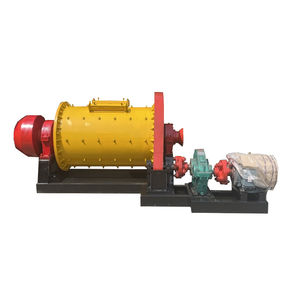

Brief introduction of Good Performance Ball Mill at Lower

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Good Performance Ball Mill at Lower refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Good Performance Ball Mill at Lower

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Good Performance Ball Mill at Lower )

Specification of Good Performance Ball Mill at Lower

A good performance ball mill at lower cost offers reliable grinding for various materials. It handles minerals, cement, ceramics, and more. The machine works efficiently for both wet and dry processes. Its design focuses on durability and energy savings. The drum is made from heavy-duty steel. This ensures resistance to wear and tear. The inner lining uses high-quality manganese or rubber. This protects the drum from abrasion. It also extends the equipment’s lifespan. The motor is energy-efficient. It reduces power consumption by up to 20% compared to standard models. This cuts operational costs over time. The ball mill’s capacity ranges from small lab-scale units to large industrial setups. Output varies between 0.5 tons per hour to 100 tons per hour. Particle size control is precise. Adjustable speed settings let users fine-tune grinding fineness. The machine operates smoothly with minimal vibration. Noise levels stay low during use. This creates a safer and more comfortable work environment. Maintenance is straightforward. Access points are strategically placed for easy inspection and part replacement. Lubrication systems are automated. This reduces manual intervention and human error. Safety features include overload protection and emergency stop buttons. These prevent damage from unexpected power surges or blockages. The ball mill supports continuous or batch processing. This flexibility suits different production needs. Spare parts are widely available. Downtime is minimized during repairs. Installation is simple. The structure is compact. It fits into existing production lines without major layout changes. Technical support is provided 24/7. Troubleshooting guides and video tutorials are included. The ball mill meets international quality standards. It undergoes rigorous testing before delivery. Certifications cover electrical safety and environmental compliance. Customization options are available. Clients can choose drum sizes, motor power, and material preferences. Bulk orders receive discounted pricing. Delivery timelines are short. Packaging is robust to prevent damage during transit. The product comes with a one-year warranty. Extended service plans are optional. User feedback highlights consistent performance and cost savings. Many industries rely on this ball mill for long-term grinding solutions.

(Good Performance Ball Mill at Lower )

Applications of Good Performance Ball Mill at Lower

A good performance ball mill at lower cost serves many industries effectively. It grinds materials into fine powder. This is key in mining operations. Ore processing needs size reduction. The ball mill crushes and grinds efficiently. Energy use stays low. Maintenance costs drop because of durable parts. This makes it ideal for long-term projects.

The cement industry benefits too. Raw materials and clinker need grinding. A reliable ball mill handles this smoothly. It works non-stop without overheating. Power consumption stays manageable. This cuts production expenses. Builders get quality cement at lower prices.

Chemical plants use these ball mills often. Mixing and grinding chemicals require precision. The machine prevents contamination. It handles abrasive substances well. Operators save time on replacements. Chemical reactions happen faster with finer particles. This boosts productivity in drug making or fertilizer production.

Metallurgy relies on ball mills for metal powder creation. Uniform particle size matters here. The equipment delivers consistent results. It works with metals like iron, copper, or gold. Processing becomes faster. Waste reduces. Factories meet high demand without delays.

Recycling units find ball mills useful. Crushing electronic waste or glass needs force. The machine breaks down tough materials easily. Recycled products gain better quality. Less energy is spent compared to traditional methods. This supports eco-friendly practices.

Agriculture sectors apply ball mills for soil treatment. Grinding minerals improves soil quality. Fertilizer production becomes efficient. Farmers get affordable options. Crop yields rise over time.

Lower-cost models keep performance high. They use advanced materials for construction. Wear-resistant parts last longer. Lubrication systems prevent breakdowns. Operators face fewer repairs. Total ownership costs stay low.

Industries value flexibility. Ball mills adjust to different materials and speeds. Settings change without complex steps. Workers train quickly. Downtime reduces. Output remains steady.

Safety features matter. Modern designs include emergency stops and protective covers. Accidents decrease. Workers feel secure. Compliance with regulations is simpler.

This equipment suits small and large operations alike. Initial investment stays reasonable. Long-term savings add up. Businesses grow without heavy spending. Quality products stay consistent. Clients trust the results.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Good Performance Ball Mill at Lower

What makes this ball mill perform well while costing less? The design focuses on efficiency. High-quality materials reduce wear. Energy-saving features cut power use. Maintenance needs stay low. This balances performance and cost effectively.

How does the ball mill handle different materials? It grinds ores, ceramics, and chemicals. Hardness and size matter. The machine adjusts rotation speed. Proper loading ensures smooth operation. Follow guidelines for best results.

Can the ball mill work in harsh conditions? Yes. It uses durable parts. Sealed components resist dust and moisture. Regular checks prevent issues. Harsh environments need extra care. The design prioritizes reliability.

What maintenance does the ball mill require? Clean it after use. Check liners and bearings often. Lubricate moving parts weekly. Replace worn parts quickly. Simple steps extend its lifespan.

How does the ball mill save energy? An optimized motor reduces power waste. Efficient grinding cuts process time. Heat generation stays low. Lower energy use means lower bills. Performance stays strong.

(Good Performance Ball Mill at Lower )

REQUEST A QUOTE

RELATED PRODUCTS