PRODUCT PARAMETERS

Description

Brief introduction of Ceramic ball mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ceramic ball mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ceramic ball mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

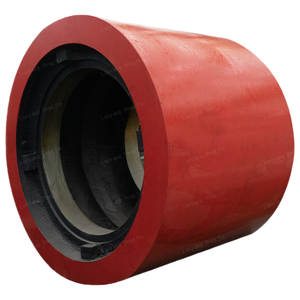

(Ceramic ball mill)

Specification of Ceramic ball mill

The ceramic round mill is built for grinding products into great powders. It works in markets such as ceramics, chemicals, and cement. The machine utilizes ceramic liners and grinding media. This prevents contamination. It matches refining delicate products. The body is constructed from high-grade steel. The inner surface area has wear-resistant ceramic plates. These plates shield the maker from abrasion. They expand the devices’s life expectancy. The drum revolves on a horizontal axis. It makes use of an electric motor with flexible speed. Users regulate grinding time and rotation speed. This readjusts the end product’s excellence. The ceramic grinding spheres be available in different dimensions. Smaller rounds develop finer fragments. Larger spheres handle rugged grinding. The machine manages both wet and dry grinding. It benefits set or continuous operations. Packing capability relies on the version. Usual designs process 50 liters to 5000 litres. Power demands vary by size. Smaller sized units need 5-10 kW electric motors. Larger devices make use of 50 kW or greater. The discharge system makes use of a display or grate. This divides grinding media from the product. Maintenance is basic. Individuals should check ceramic liners on a regular basis. Replacing worn liners avoids breakdowns. Lubrication points are easy to accessibility. The equipment runs silently. Vibrations are very little. This reduces sound in the workplace. Energy effectiveness is an essential function. The layout reduces power waste. Heat generation remains reduced throughout procedure. This safeguards heat-sensitive products. Installment needs a solid foundation. Proper positioning ensures smooth performance. Safety attributes consist of overload protection. Emergency stop switches are typical. The ceramic sphere mill fits labs and manufacturing facilities. It grinds minerals, pigments, and clays. Personalized alternatives consist of additional linings or specialized electric motors. Cleaning is uncomplicated. Water or solvents eliminate residue. The maker resists chemical rust. It does well in extreme atmospheres. Resilience makes it affordable in time. Technical assistance is readily available for fixing. Spare parts are commonly available. Training makes certain drivers utilize the equipment appropriately. Normal examinations stop unexpected downtime. The ceramic round mill fulfills international safety criteria. It balances performance and integrity.

(Ceramic ball mill)

Applications of Ceramic ball mill

Ceramic ball mills grind materials right into fine powders. They utilize ceramic liners and grinding spheres. These components stand up to wear. They do not react with processed materials. This makes them optimal for sectors requiring pureness.

Mining procedures make use of ceramic sphere mills. They grind ores and minerals. Metal devices can introduce impurities. Ceramic avoids this. Smelting then produces purer metals.

The chemical market relies upon ceramic ball mills. Blending and grinding chemicals prevails. Steel tools risks unwanted reactions. Ceramic addresses this. Heat-sensitive compounds need careful handling. Ceramic mills manage this efficiently.

Ceramics producing depends on these mills. Resources like clay need fine grinding. Ceramic mills create smooth blends. They likewise grind lusters and pigments uniformly. Ended up items have regular high quality.

Pharmaceutical firms use ceramic sphere mills. Medicines need high purity. Steel contamination threats patient safety and security. Ceramic avoids this. Great powders for tablet computers or shots are created dependably.

Food processing gain from ceramic round mills. Active ingredients like flavors need grinding. Hygiene standards are rigorous. Ceramic is non-toxic. It stands up to corrosion. Cleaning up is simple. Food remains secure and consistent.

Environmental modern technology applies ceramic ball mills. Reusing materials like digital waste is one example. Hard materials require damaging down. Ceramic mills handle this. Valuable metals obtain recuperated without pollution.

These mills work in laboratories too. Study calls for accurate material prep work. Ceramic ensures no interference. Experiments remain precise.

Durability matters. Ceramic parts last longer than steel. Upkeep expenses decline. Downtime decreases. Workflow remain reliable.

Personalization is feasible. Various ceramic types suit specific requirements. Alumina or zirconia linings prevail. Users pick the best fit.

Energy effectiveness is an and also. Ceramic mills often utilize less power. Processing stays cost-effective. Companies conserve resources.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ceramic ball mill

Ceramic ball mills grind materials using rotating cylinders filled with ceramic balls. The cylinder rotates. The balls drop and crush the material inside. Friction and impact break particles into fine powder. This process ensures even grinding.

What materials can a ceramic ball mill handle? It works for hard minerals, ceramics, cement, and metal ores. Ceramic linings resist chemical reactions. This makes it suitable for corrosive or heat-sensitive materials. Avoid grinding substances harder than the ceramic balls. This prevents damage.

Why choose a ceramic ball mill over steel ones? Ceramic mills avoid metal contamination. This is critical for industries like electronics or pharmaceuticals. Ceramic parts last longer in abrasive environments. Energy use is lower due to lighter grinding media.

How often should maintenance be done? Inspect linings and balls every 200-300 hours. Replace worn ceramic parts immediately. Lubricate bearings monthly. Clean the mill after each use to prevent material buildup. Follow the manufacturer’s guidelines for specific intervals.

What affects grinding efficiency? Rotation speed matters. Too fast, balls stick to the walls. Too slow, they don’t impact properly. Material size should be uniform before grinding. Overloading reduces contact between balls and particles. Adjust ball size and quantity based on material hardness.

What capacity options exist? Sizes range from lab-scale models to industrial units. Capacity depends on cylinder volume. Industrial mills handle tons of material daily. Choose based on production needs. Custom configurations are available for specific requirements.

(Ceramic ball mill)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Vertical Lead Oxide Aluminum Powder Ball Mill Ceramic Balls For Ball Mill

Mini ball mill for coal

Ballmill Small Mining Ball Mill