PRODUCT PARAMETERS

Description

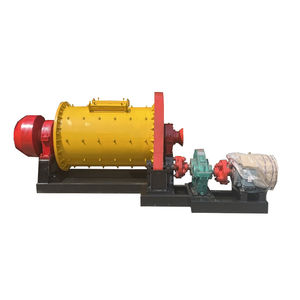

Brief introduction of Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill)

Specification of Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill

The sphere mill is a crucial machine for grinding products like coal, gold ore, and various other powders. It turns raw materials into great bits for industrial usage. Three versions are readily available: 900X1200, 900X3000, and 1800X4500. These numbers show the drum’s size and length in millimeters. The layout fits various production requirements, from small-scale tasks to large operations.

The 900X1200 model is portable. It works well for laboratories or pilot projects. The drum holds sufficient material for stable grinding. The 900X3000 model is longer. It increases capacity for medium-sized processing. The 1800X4500 version is the largest. It handles high-volume grinding with performance. All designs make use of thick steel plates. Welded joints guarantee stamina. The framework stands up to wear from heavy usage.

Each round mill makes use of steel spheres inside the revolving drum. Products enter one end. They get squashed as the drum spins. The ground powder leaves through a display. Electric motor power varies by design. The 900X1200 uses a 15 kW motor. The 900X3000 requires 30 kW. The 1800X4500 requires 90 kW. Rate gets used to manage grinding excellence. Higher speeds create finer powders.

These ball mills operate in mining, cement plants, and ceramics. They grind gold ore for removal. They refine coal for fuel production. They blend raw materials in concrete production. Consistent particle dimension enhances product high quality. Output ranges from 0.5 to 50 tons per hour, depending upon the version.

Security functions include protected covers over relocating parts. Emergency situation quit buttons prevent accidents. Routine maintenance is simple. Accessibility panels let employees examine interior components. Lubrication points lower friction. Replaceable linings extend the drum’s life.

Personalized options are readily available. Choose various linings for certain materials. Add automated control systems for specific operation. Select electric motor kinds based upon regional power requirements. The sphere mill adapts to different sectors. It balances efficiency with dependability.

(Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill)

Applications of Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill

Round mills with sizes like 900×1200, 900×3000, and 1800×4500 are developed for grinding materials into great powders. These models handle tough jobs in mining, construction, and chemical sectors. They work well for grinding coal, gold ore, and other minerals. The equipments turn resources into consistent bits, which is essential for quality assurance in manufacturing.

The 900×1200 design is small. It matches little to medium procedures. It grinds materials effectively without taking up much room. The 900×3000 design supplies greater ability. It fits larger tasks needing continuous grinding. The 1800×4500 design is sturdy. It deals with industrial-scale work, perfect for huge plants refining bulk materials like coal or gold ore.

All models utilize sturdy steel shells. The inner lining is changeable. This secures the mill from wear during grinding. Steel or ceramic spheres inside crush products by rotating with the drum. The rate can be readjusted. This regulates the grinding fineness. Faster rotation develops better powders.

These round mills are energy-efficient. They minimize power use while maintaining output. Motors are built to run smoothly under hefty lots. Maintenance is easy. Accessibility points enable easy assessment and component substitute. This cuts downtime and repair costs.

Safety attributes include overload protection. The system quits automatically if temperatures or vibrations exceed limitations. Sealed styles prevent dirt leaks. This keeps offices tidy and secure. Operators can keep track of efficiency with control panels. Settings are flexible for various materials and outcome requirements.

The sphere mills operate in cement manufacturing, metal processing, and chemical manufacturing. They grind limestone, clinker, and ores for concrete blending. In gold handling, they grate ore to essence metals. Coal is ground to powder for gas or industrial uses.

Personalization is offered. Linings, round sizes, and drive systems can be tailored. This guarantees compatibility with details products or workflows. The devices are constructed to last. They stand up to rust and mechanical anxiety. Routine maintenance expands their service life.

These ball mills balance performance and price. They meet strict sector criteria. Their designs concentrate on integrity and user safety. They are practical solutions for companies needing regular, top quality powder grinding.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill

What is a ball mill used for? A ball mill grinds materials into fine powder. It works by rotating a cylinder with steel balls inside. The materials get crushed by the balls as the cylinder turns. This machine is common in mining and construction. It handles coal, gold ore, and other minerals. The process ensures even grinding for consistent results.

What sizes do these ball mills come in? The models include diameters of 900x1200mm, 900x3000mm, and 1800x4500mm. Size affects capacity and grinding efficiency. Smaller mills suit labs or small batches. Larger ones handle industrial-scale operations. The 1800x4500mm model processes more material per hour. Choose based on your production needs.

What materials can these ball mills grind? They work for coal, gold ore, cement, and silicates. They also process ceramics and chemicals. Hard or brittle materials grind well. Moisture content should stay low. Wet grinding is possible with certain setups. Check the material specs before use.

How do I maintain a ball mill? Regular checks prevent breakdowns. Lubricate gears and bearings often. Inspect the lining and steel balls for wear. Replace damaged parts quickly. Clean the machine after each use. Follow the manual for motor and electrical safety. Proper upkeep extends the machine’s life.

Can the ball mill be customized? Yes. Liners and grinding media can be adjusted. Motor power and rotation speed vary by model. Some setups include cooling systems. Custom sizes need factory approval. Share your requirements with the supplier. They will suggest the best options.

The ball mill’s design ensures durability. Heavy-duty steel construction handles tough jobs. The motor provides steady power. Safety features protect operators. Always follow guidelines for installation. Training staff reduces operation risks. Reliable performance makes it a key tool in grinding.

(Ball Mill Diameter 900X1200 900X3000 1800X4500 Model Ball Mils For Coal Gold Ore Powder Grinding Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Wear resistant non-standard Heavy Machinery Ball Mill Parts large Casting Liner Plate

Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

Source factory ball mill wear-resistant parts lining plate

Wet Ball Mill Spare Parts Ball Mill for in Zimbabwe

Ball Mill Powder Mill for Mineral Processing Small Overflow Type Mixed Mercury High Manganese Steel Ball Mill