PRODUCT PARAMETERS

Description

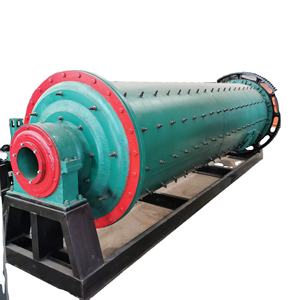

Brief introduction of Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill)

Specification of Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill

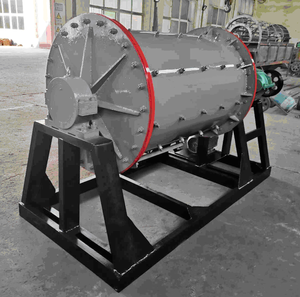

The round mill and spiral classifier lab tube mill configuration is made for grinding and dividing products in lab settings. The round mill uses grinding balls to crush and mix samples. It deals with a spiral classifier to arrange particles by dimension. This setup is common in mining, porcelains, and chemical labs.

The ball mill has a stainless-steel or ceramic grinding chamber. The chamber holds grinding spheres constructed from steel, ceramic, or various other durable products. The motor power varies from 0.5 kW to 2.2 kW. Rotation speed changes between 50 to 300 RPM. The chamber capacity differs from 1 litre to 10 litres. The maker consists of a digital timer and speed control. It supports dry and damp grinding modes.

The spiral classifier connects to the sphere mill. It separates fine and coarse particles using a spiral rotor. The classifier body is built from corrosion-resistant materials like stainless-steel or polyurethane. The spiral speed changes in between 2 to 20 RPM. The inclination angle of the classifier can be changed. This aids control the splitting up effectiveness. The classifier processes approximately 5 lots of material per hour in continuous operation.

Lab tube mills are smaller versions for specific example preparation. They manage sets from 100 grams to 2 kilos. These mills feature variable speed settings and compact layouts. They fit conveniently on lab benches. The grinding containers are interchangeable. Customers can select jar materials based upon example requirements.

Grinding balls can be found in sizes from 5 mm to 30 mm. They are constructed from high-chromium steel, stainless steel, or zirconia. Zirconia spheres stand up to wear and chemical corrosion. Steel rounds match general-purpose grinding. The firmness of grinding spheres arrays from 55 HRC to 65 HRC. Correct round size and product selection make sure reliable grinding.

The system operates quietly with marginal resonance. Safety features include overload defense and emergency situation quit buttons. All components fulfill industrial safety and security standards. Normal upkeep prolongs the devices life-span. Cleaning up is simple because of smooth surface areas and removable components.

(Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill)

Applications of Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill

Sphere mills are utilized to grind products into great powders. They work by turning a cyndrical tube with steel spheres inside. The balls crush and grind the product. This procedure prevails in mining, cement, and chemical sectors. Ores, concrete clinker, and porcelains are normal materials refined. The dimension of the final product relies on the grinding time and round dimension.

A spiral classifier pairs with a sphere mill to separate particles by dimension. It uses a spiral blade to lift rugged product for regrinding. Great bits flow out with water. This ensures effective dimension sorting in mineral processing. It minimizes overgrinding and saves energy. The classifier is simple to operate and maintain.

Lab tube mills are smaller versions of sphere mills. They are used for screening material grindability. Scientists readjust variables like speed and ball cost. This aids maximize major production. Laboratory mills are important for quality control. They permit exact modifications prior to large financial investments.

Grinding balls are important for sphere mill performance. They are made from steel, ceramic, or other alloys. Hardness and density impact grinding efficiency. Steel spheres are durable and affordable. Ceramic rounds stand up to deterioration and match damp grinding. Correct sphere dimension option ensures consistent bit dimension. Used balls need to be replaced to maintain performance.

Sphere mills and spiral classifiers create an essential system in mineral handling. They deal with tasks from coarse grinding to great category. Laboratory tube mills provide data for scaling up procedures. Grinding balls straight affect milling costs and output quality. Regular upkeep of devices prolongs service life. Correct procedure minimizes downtime and boosts effectiveness.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill

A ball mill is equipment used to grind materials into fine powder. It works by rotating a cylinder with grinding media like steel or ceramic balls. The balls collide with the material, crushing it to the desired size. This process is common in labs and industries for mixing and grinding chemicals, ores, and other substances.

Grinding balls inside a ball mill crush materials through impact and friction. As the mill rotates, the balls lift and drop, hitting the material. Smaller balls create finer particles. Larger balls handle tougher materials. The choice of ball material affects wear resistance and contamination risks. Steel balls are durable. Ceramic balls suit contamination-sensitive applications.

A spiral classifier sorts particles by size in a lab tube mill setup. It uses a spiral mechanism to separate ground material into fine and coarse fractions. The coarse particles return to the mill for regrinding. The fine particles move to the next processing stage. This ensures consistent product quality and efficient grinding.

Picking the right grinding balls depends on material hardness, particle size goals, and mill operation conditions. Steel balls work for most metals and ores. Ceramic or glass balls are better for delicate materials like pigments. Ball size matters. Smaller balls grind finer. Larger balls handle coarse feed. Match ball hardness to the material’s abrasiveness to reduce wear.

Regular maintenance keeps ball mills and grinding balls working well. Check the mill’s lining and bolts for wear or looseness. Clean the mill to prevent material buildup. Inspect grinding balls for cracks or excessive wear. Replace damaged balls quickly. Lubricate moving parts as the manual says. Monitor motor and gear performance. Proper maintenance avoids breakdowns and extends equipment life.

(Ball Mill And Sprial Classifier Lab Tube Mill Grinding Balls For Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Direct Durable High Quality Casting Ore Ball Mill Motor For Ball Mill For

Diatomaceous earth powder ball mill plant ,Baichy the professional crushing equipment

High Chrome Manganese Alloy Cement and Mining Ball Mill Grinding Media Shell Liner Plate Wear Parts