PRODUCT PARAMETERS

Description

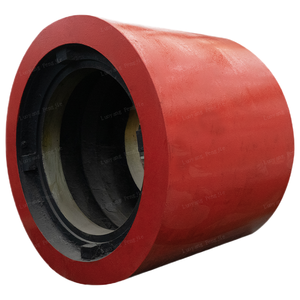

Introduction to towed Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts)

Specification of Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

Small excavator track base roller undercarriage components are vital. They maintain your device relocating efficiently. These rollers rest under the track chain. They support the entire weight of the excavator. They lead the track as it conforms the ground. Consistent call with difficult surfaces takes place. Rocks, dust, debris struck them daily. This demands severe durability.

Sturdy steel makes these rollers. Usually heat-treated steel is used. This makes them extremely solid. It aids them stand up to flexing or damaging. Sealed bearings are inside most rollers. This keeps dust and water out. Lubrication stays inside the bearing. This lowers wear. It makes the rollers last much longer. Good seals are essential here.

Changing worn lower rollers issues. Old rollers cause problems. They make the tracks run unevenly. This stress various other undercarriage components. Idlers and gears use faster. Track tension experiences. Gas performance declines. Device stability really feels less safe and secure. Examining roller condition is normal maintenance. Seek noticeable fractures or damages. Pay attention for grinding sounds. Excessive wobble implies difficulty. Replace rollers in collections usually. This maintains every little thing balanced.

Our heavy tools spare parts are built right. Specific dimensions match original specifications. Dependable efficiency is the goal. High-grade products make certain durability. Appropriate sealing secures the bearings. These components fit significant mini excavator brands. They supply dependable service life. Your maker needs strong support underneath. Quality bottom rollers provide that foundation. They maintain your miniature excavator working hard.

(Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts)

Applications of Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

Small excavator track bottom rollers are essential undercarriage components. They support the equipment’s weight and overview the track chain efficiently over the framework. This keeps the excavator steady and relocating appropriately on harsh ground. Without excellent rollers, the whole device experiences. These components take heavy penalty daily. They face rocks, mud, particles, and consistent motion. Put on is unpreventable with time. Used rollers create huge issues. They make tracks thwart more frequently. This stops work and threats security. Bad rollers also strain various other undercarriage parts like idlers and sprockets. Changing them swiftly conserves cash later on. It stops larger, costlier fixings. Utilizing high-grade substitute rollers matters a lot. Good rollers last much longer. They handle laborious much better. They are built strong from difficult steel alloys. Correct heat treatment makes them immune to wear. Sealed bearings stay out dirt and water. This lubrication lasts much longer. Choosing the ideal roller size and type is important. It should match your particular excavator design and the work site problems. Farms, construction areas, and forestry job demand resilient rollers. Tiny excavators dig trenches, clear land, and do demolition. Their undercarriage works hard. Reputable lower rollers indicate much less downtime. They keep the equipment effective. Operators notification smoother motion. The machine remains stable on inclines. Replacing worn rollers is fundamental upkeep. It safeguards your financial investment. It makes sure the excavator works accurately job after task. Great undercarriage components mean the device lasts.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts

What exactly is a bottom roller?

Bottom rollers support the excavator’s weight. They keep the track moving smoothly over the ground. They sit right under the track chain. Without them, the machine can’t move properly.

How do I know mine need replacing?

Look for obvious signs of damage first. Cracks or deep dents are bad news. Check for uneven track sagging too much. Listen for grinding or squealing noises when driving. Excessive vibration while operating means trouble. Leaking grease seals are another clear warning sign. Ignoring these leads to bigger problems.

How often should I replace them?

There’s no fixed schedule. It depends entirely on how you use the machine. Tough jobs on rocky ground wear them out faster. Regular work in soft mud is easier on parts. Always inspect them during routine maintenance. Compare wear between rollers. Replace them when they show significant damage or uneven wear.

Can I use any brand of bottom roller?

No, using the wrong roller causes problems. You need the exact part designed for your excavator model. Wrong sizes or specs strain the track system. This wears out other parts quickly. Genuine OEM parts guarantee the perfect fit. Quality aftermarket brands work well too, but double-check compatibility first.

Is replacing them difficult?

Replacement requires mechanical skill and proper tools. You need to safely lift the machine. You must remove the track tension first. Handling the heavy track sections is demanding. Incorrect installation risks damaging the new roller or track. Many owners hire a qualified technician for this job. It saves time and avoids costly mistakes.

(Mini Excavator Track Bottom Roller Undercarriage Parts Heavy Equipment Spare Parts)

REQUEST A QUOTE

RELATED PRODUCTS

4D94-1 4D94-2 4D94-3 cylinder head assy for Komatsu PC100-1 PC100-2 PC200 PC320D PC200-8 excavator engine parts

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks

cheap original engine HD1430 EXCAVATOR 210W-9 210lc-5 215c-9 305-9 ZX50 ZX200 ZX240G EX60 ZX180 ZX130 ZX120 ZX350

300*52.5*78 excavator track suit for DH360 DH300 DH200 excavators skid steer loader rubber tracks for excavator s

Heavy equipment spare parts undercarriage parts for excavator