PRODUCT PARAMETERS

Description

Brief introduction of Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

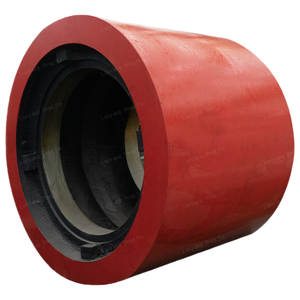

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding)

Specification of Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

The Large Horizontal Planetary Ball Mill is designed for efficient grinding of various materials into fine powders. It handles hard substances like minerals, ceramics, and metals. The machine achieves a consistent output of 50 mesh or finer. Its horizontal layout ensures stable operation during high-speed rotations. The planetary movement of grinding jars enhances grinding efficiency by creating strong centrifugal forces. This action breaks down particles through impact and friction between grinding balls and materials.

The machine includes multiple grinding jars made from durable materials like stainless steel or tungsten carbide. Jar sizes vary to accommodate different batch needs. Users can adjust rotation speed to control grinding fineness. The 50 mesh output suits applications requiring medium-fine powders. It works well in industries like mining, construction, and metallurgy.

This ball mill processes both dry and wet materials. It supports continuous or batch operations based on production demands. The sealed design prevents dust leakage, maintaining a clean workspace. Safety features include a locking system for jar lids and overload protection. The motor is energy-efficient, reducing power consumption during long runs.

Grinding balls come in sizes from 5mm to 20mm. Users select ball size based on material hardness and desired particle size. The machine’s structure uses heavy-duty steel for vibration resistance. Noise levels remain low due to precision engineering and shock-absorbing components. Maintenance is simple, with easy access to parts like bearings and belts.

The control panel offers timers and speed settings for automated operation. A digital display shows real-time data like RPM and running time. Cooling systems prevent overheating during extended use. The compact design saves floor space while ensuring robust performance.

This ball mill suits labs and industrial settings. It grinds materials like cement, ores, and ceramics effectively. The stone-grinding function delivers uniform particle distribution. Users benefit from quick sample processing and repeatable results. Optional accessories include jar holders, ball separators, and spare liners.

The machine meets international safety and quality standards. It is built for long-term use with minimal wear. Operators receive clear instructions for setup and troubleshooting. Technical support is available for maintenance or part replacements.

(Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding)

Applications of Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

The Large Horizontal Planetary Ball Mill handles high-efficiency grinding tasks. It processes hard materials like metals, ceramics, and minerals. This machine suits industries such as mining, construction, and laboratory research. Its horizontal design allows even distribution of grinding energy. This ensures consistent particle size reduction. It works well for both dry and wet grinding. Users achieve fine powders for advanced manufacturing processes. The machine supports large-scale production. It also adapts to small-batch experimental needs.

The 50 Mesh Ball Mill focuses on producing particles sized to 50 mesh. This equals 300 microns. It serves industries needing precise granular control. Examples include chemical processing, paint production, and construction materials. The mill crushes raw materials into uniform 50-mesh powders. This consistency improves product quality in mixing or coating applications. The machine operates with low energy consumption. It reduces operational costs over time. Its structure is simple. Maintenance stays straightforward.

The Ball Mill Machine for Stone Grinding specializes in processing natural stones. It turns materials like marble, granite, and quartz into fine powders. These powders apply to construction, decoration, and industrial uses. The machine grinds stones smoothly. It creates even surfaces for tiles or countertops. It also produces raw material for composite products. The grinding process minimizes waste. It maximizes material utilization. The machine’s durable construction handles heavy loads. It resists wear from abrasive stone particles.

All three machines prioritize user safety. They include features like overload protection and secure locking systems. Operators control settings easily. Adjustments optimize performance for different materials. Regular cleaning prevents cross-contamination. These mills suit diverse environments. They work in factories, workshops, and research labs. Their versatility makes them essential for modern material processing.

The Large Horizontal Planetary Ball Mill handles tough grinding tasks reliably. The 50 Mesh Ball Mill delivers exact particle sizes efficiently. The Ball Mill Machine for Stone Grinding transforms raw stone into usable forms effectively. Each machine meets specific industrial demands. They improve productivity across multiple sectors.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding

What is the Large Horizontal Planetary Ball Mill used for? It grinds materials into fine powders. Industries like mining, ceramics, and chemistry use it. It mixes materials evenly. It handles hard or soft substances. It works for both dry and wet grinding. What capacity does this machine have? It processes 100 to 500 liters per batch. The size depends on jar volume. It supports multiple jars at once. It runs continuously for hours. It suits lab tests or large production. How fine can the 50 Mesh Ball Mill grind materials? It achieves particles as small as 50 mesh. The mesh size equals 0.3 millimeters. It crushes materials through collision. The grinding time affects fineness. Adjust speed for coarser or finer results. What materials work with the stone-grinding ball mill? It processes granite, quartz, limestone. It avoids sticky or moist substances. The machine uses stainless steel or ceramic balls. It resists wear from abrasive materials. It polishes stones for construction or art. How do I maintain these ball mills? Clean jars after each use. Check belts and motors monthly. Lubricate gears every 500 hours. Replace worn grinding balls. Keep the machine dry to prevent rust.

(Large Horizontal Planetary Ball Mill,50 Mesh Ball Mill, Ball Mill Machine Stone Grinding)

REQUEST A QUOTE

RELATED PRODUCTS

Low worth buying products Mining Grinding Mill Trommel Scrubber Wear Parts Rubber Ball Mill Liner For

Cement Plant Large Diameter Zg35 Ball Mill Head Ball Mill End Cover

Cost-Effective Ball Mill for Maximum Milling Efficiency

Custom Different Size End Cap Ball Mill Spare Parts Mining Machinery Ball Mill End Cover