PRODUCT PARAMETERS

Description

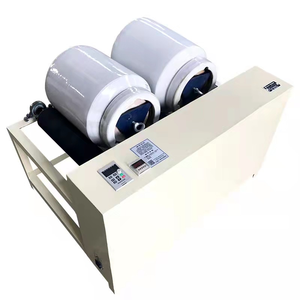

Brief introduction of Ball Mill Supply Grinding Machine Stone Grinding Ball Mill

Ball mill is a kind of equipment used to crush or grind materials to very fine powder, which is widely used in mining, cement, chemical industry, etc. Ball Mill Supply Grinding Machine Stone Grinding Ball Mill refers to all kinds of parts and components which are necessary to ensure the normal operation of the ball mill, including liner plate, grinding balls, gears, bearings and so on.

Features and advantages of Ball Mill Supply Grinding Machine Stone Grinding Ball Mill

Strong durability: Made of high-quality materials and under strict quality control, it ensures high wear resistance and long service life of spare parts.

Good interchangeability: The standardized design makes the spare parts interchangeable between different types of ball mills, simplifying the maintenance process.

Optimized design: Customised design according to the actual working conditions, which improves the working efficiency and reduces energy consumption at the same time.

Easy to install and maintain: reasonable structure, convenient for users to quickly replace and repair, reduce downtime.

Stable performance: Precision machining and rigorous testing ensure stable performance even in harsh environments.

(Ball Mill Supply Grinding Machine Stone Grinding Ball Mill)

Specification of Ball Mill Supply Grinding Machine Stone Grinding Ball Mill

The Sphere Mill Grinding Device is made to grind materials into great powder for industrial use. It manages cement, silicates, porcelains, plant foods, and non-ferrous steels. The machine is built to last with solid steel or rubber linings. It is available in horizontal and upright styles to fit different needs. The grinding process starts when the cylinder rotates. Steel spheres or rods inside crush the materials into smaller bits. Fragment dimension is managed by adjusting turning speed or grinding media type.

This round mill works for both completely dry and damp grinding. Dry grinding generates fine powders. Damp grinding creates slurries for blending. The equipment’s ability varies from 0.5 to 100 heaps per hour. Electric motor power varies between 15 kW and 2000 kW depending upon version size. Turning speed is adjustable for precise results. Safety functions consist of overload defense and automatic cooling systems. These prevent overheating throughout long procedures.

The ball mill is made use of in mining, building, and chemical markets. It refines ores, cement clinker, and raw materials. Its layout guarantees even fragment circulation. This enhances product top quality. Energy-efficient electric motors reduce power use. Low upkeep is a vital advantage. Components like linings and grinding media are easy to replace. Access panels permit fast inspections without quiting production.

Durable products like state-of-the-art steel expand the maker’s lifespan. Rust-resistant coverings protect against wear. Sound levels are kept low for safer work environments. The compact style saves space in factories. Customized sizes are readily available for details requirements. Installment is straightforward with provided standards. Technical assistance is offered for arrangement and troubleshooting.

The grinding chamber is secured to stop dust leakages. This keeps the workplace clean. Regular lubrication points make sure smooth procedure. Operators can check efficiency through control panels. Real-time data aids change settings for optimum output.

(Ball Mill Supply Grinding Machine Stone Grinding Ball Mill)

Applications of Ball Mill Supply Grinding Machine Stone Grinding Ball Mill

A sphere mill is a vital maker made use of to grind materials right into fine powder. It operates in mining, building and construction, chemical markets, and much more. The grinding procedure occurs inside a revolving cyndrical tube full of grinding media like steel spheres. These spheres crush and grind the material into the preferred fineness. The Supply Grinding Machine Rock Grinding Ball Mill manages various materials, including ores, concrete, ceramics, and chemicals. It is developed for durable usage and lasting integrity.

In mining, round mills procedure ores to draw out metals like gold, copper, and iron. The ore is fed into the mill, ground by the steel balls, and separated into functional steel focuses. Cement plants depend on ball mills to grind raw materials and produce clinker. This clinker is mixed with additives to create cement. The constant grinding makes sure premium final products.

Ceramic sectors use ball mills to blend and grind materials like clay and feldspar. The great powder created is shaped right into ceramic items and terminated in kilns. Chemical plants use sphere mills to crush raw chemicals right into powders for producing plant foods, dyes, and finishes. The process permits specific control over fragment size, improving item efficiency.

The Supply Grinding Equipment Rock Grinding Ball Mill includes a tough layout with a revolving drum and durable linings. It minimizes wear and prolongs service life. The machine operates efficiently with very little vibration, ensuring stable efficiency. Individuals readjust rotation rate and grinding time to accomplish various excellence levels. It sustains both dry and damp grinding techniques, adapting to diverse material needs.

This round mill matches little laboratories and huge factories. Its basic structure makes setup and upkeep easy. Operators conserve time and costs with efficient grinding and low power consumption. The equipment’s versatility covers sectors from metallurgy to drugs. Routine upkeep maintains it running effectively. Appropriate lubrication and part inspections stop malfunctions. The Supply Grinding Equipment Stone Grinding Ball Mill provides trusted outcomes for material handling needs.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Ball Mill Supply Grinding Machine Stone Grinding Ball Mill

A ball mill grinds materials into fine powder. It is used in mining, construction, and chemical industries. The machine has a rotating cylinder filled with steel balls. Materials are fed into the cylinder. The rotation causes the balls to hit the materials, crushing them into smaller particles. The final powder size can be adjusted by changing the rotation speed or grinding time.

Ball mills process ores, ceramics, cement, and chemicals. Hard materials like quartz or granite work well. Soft or sticky materials might cause clogging. Moisture content should stay low. Wet grinding is an option for some materials. The machine handles both dry and wet processes.

Maintenance requires checking lubrication levels regularly. Bearings and gears need proper oil to avoid overheating. Inspect the liners and balls for wear. Replace them if cracks or excessive wear appear. Clean the mill after use to prevent residue buildup. Follow the manufacturer’s schedule for part replacements.

Efficiency depends on rotation speed. Too fast or too slow reduces grinding effectiveness. Ball size and material matter. Larger balls crush coarse materials. Smaller ones create finer powder. The amount of material loaded affects output. Overloading slows grinding. Underloading wastes energy. Match the mill’s capacity to your needs for best results.

Safety steps include securing the machine before operation. Check electrical connections and guards. Wear protective gear like gloves and goggles. Keep loose clothing away from moving parts. Never open the mill while it’s running. Follow emergency stop procedures if issues arise. Training operators reduces accident risks.

(Ball Mill Supply Grinding Machine Stone Grinding Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Factory whole of various types of iron ore ball mill equipment

Rotary kiln and cement ball mill spare pasts wheel and ring gear casting girth gear large steel spur gear

s Large diameter ball mill bull gear forging ZG45 cement rotary kiln spur girth ring